To distribute

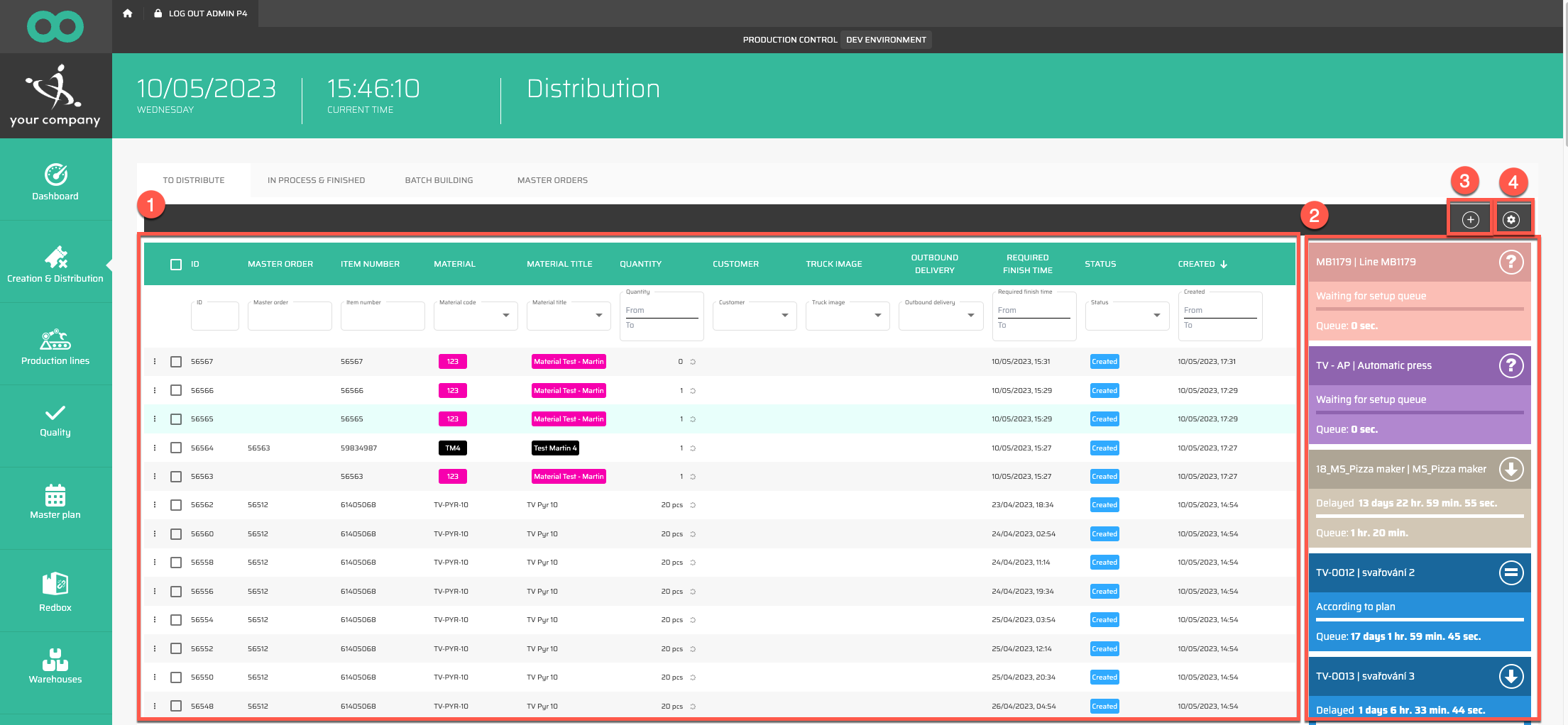

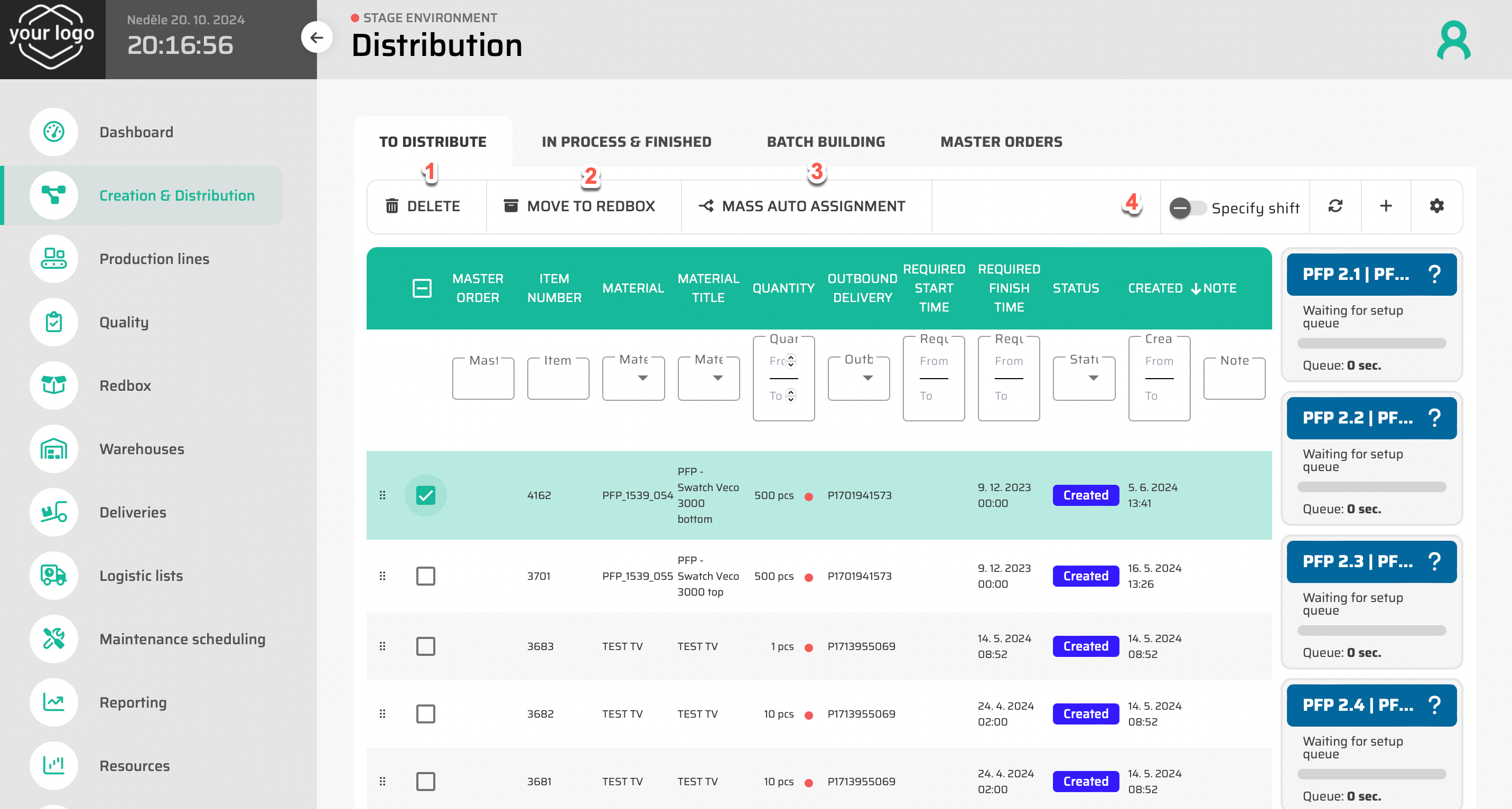

Tab To distribute (also called distribution table) is a table, where you are able to create production items and assign them to production lines. To access this page it is needed to have respective permission assigned at least one of your user roles (permission name: Production Control → Creation And Distribution → Distribution Table).

There are several section in this page:

Left section - which contains all production items in status created.

Right section - box for all production lines which meets the following criteria:

The production line has to be active.

Logged user is connected to this production line.

There is at least one production item with material that can be produced on this production line (production time has to be set and this connection has to be active).

In case the production line is part of a long line chain, the last line from the chain will be visible here.

Button

to create a new production item.

to create a new production item.Button

to manage page layout.

to manage page layout.

The list of all created production items can be filtered by all shown columns, it means by:

ID

Master order

Item number

Material

Material title

Quantity

Customer

Truck image

Shipping time

Outbound delivery

Scheduled finish time

Scheduled delivery time

Ideal finish time

Required start time

Required finish time

Handling unit template

Status

Created

Is Master order

Comment

Producible lines

Department

Material type

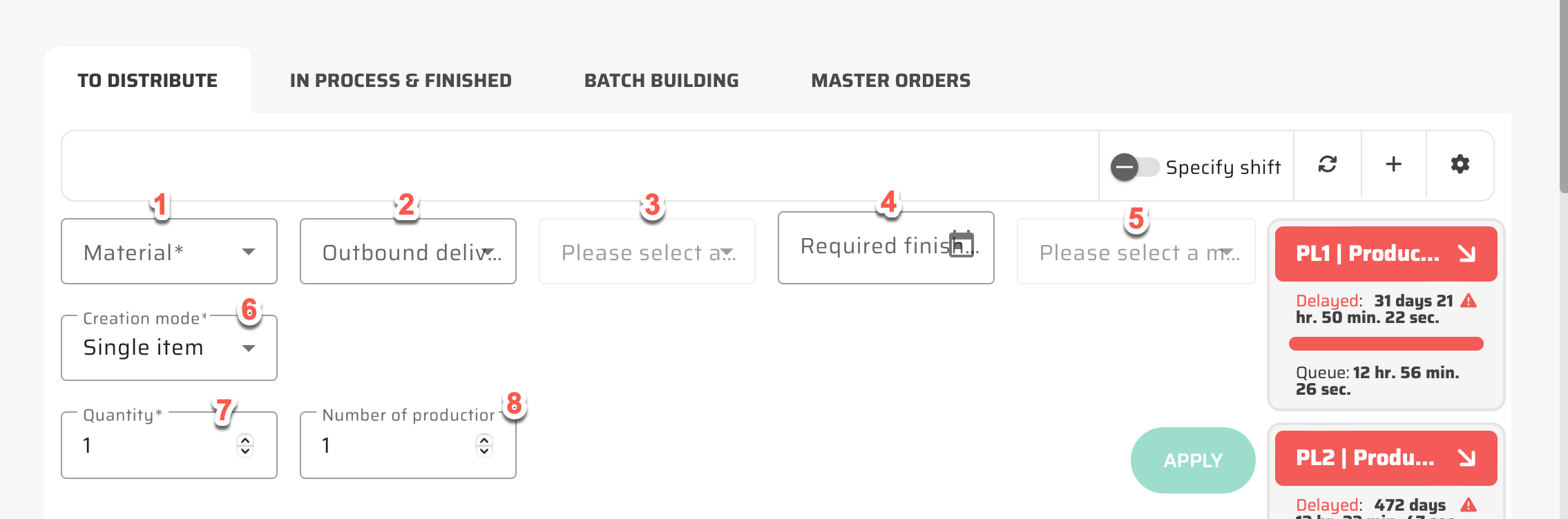

Creation of new production item

With the button ![]() you can create a new production item:

you can create a new production item:

It the table below you will find all attributes which are possible to insert into this dialog together with its description.

# | Parameter name | Limitations | Possible values | Description |

|---|---|---|---|---|

1 | Material* | defined values | list of all materials in the system | Material, which I want to produce. |

7 | Quantity* | 0 or positive number | number | Quantity, which I want to produce. |

2 | Outbound delivery | defined values | list of all Outbound Deliveries in the system (except the ones in status “Shipped” or “Deleted”). |

|

3 | Outbound delivery material | defined values | list of all Outbound Delivery materials related to selected Outbound Delivery |

|

4 | Required finish time | timestamp | HH:MM:SS DD/MM/YYYY |

|

6 | Creation mode* | defined values |

| This parameter is driving the process of production item creation. For more information, please check the process page. |

7 | BOM selection | defined values | list of all BOMs available for selected material |

|

5 | Link items | checkbox | on / off | This parameter is driving the process of production item creation. For more information, please check the process page. |

8 | Number of production items* | positive number | number | In case of need to create more than one production item, it is possible to change this value from default one to another number and so there will be more exactly same production items created. |

BOM stands for bills of materials, which are used for products that require components, semi-finished, or raw materials for their production. By creating a BOM, the system automatically generates all necessary production items based on the requirements, streamlining the production process and ensuring all necessary components are available for manufacturing

The button ![]() opens the Layout for this data table.

opens the Layout for this data table.

To improve visibility and prioritize materials, you have the option to use color-coding in the parameter settings. This allows you to easily identify materials that require special attention or have a higher priority in the production process, streamlining workflow and ensuring efficient use of resources.

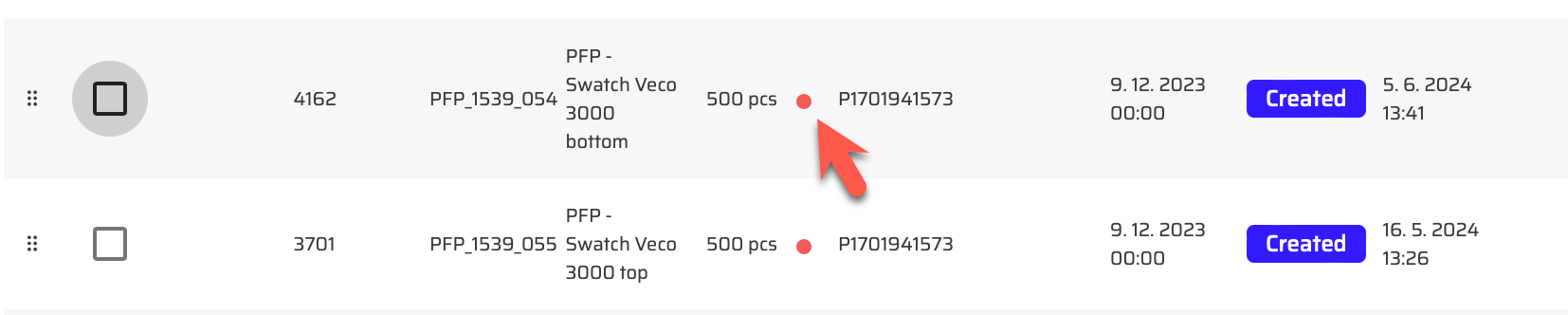

The dot on the screen indicates the items from the bill of materials needed to make the product, along with the required quantity. The color of the dot represents the current status of the pieces in stock, providing a visual cue on their availability and ensuring that the production process can proceed smoothly:

Red = there are not enough pieces in stock

Blue = there are enough pieces in stock

If you select with checkbox a specific item/s, you are able to:

Delete

Move to Redbox

Mass auto assigment

Distribute them manually

The production lines on which the material can be produced will be shown on the right.

Assignment to Production Line

The main purpose of the Distribution table is to assign Production Items to the Production Lines. This process can be done in several ways:

Manual assignment

Mass assignment

Auto assignment

Manual assignment

It is possible to Drag&Drop Production Item (or multiple items by selecting them with checkboxes) to the specific Production lines. During this process only relevant Production Lines are displayed and therefore is ensured, that Production Item can be assigned only to the right lines.

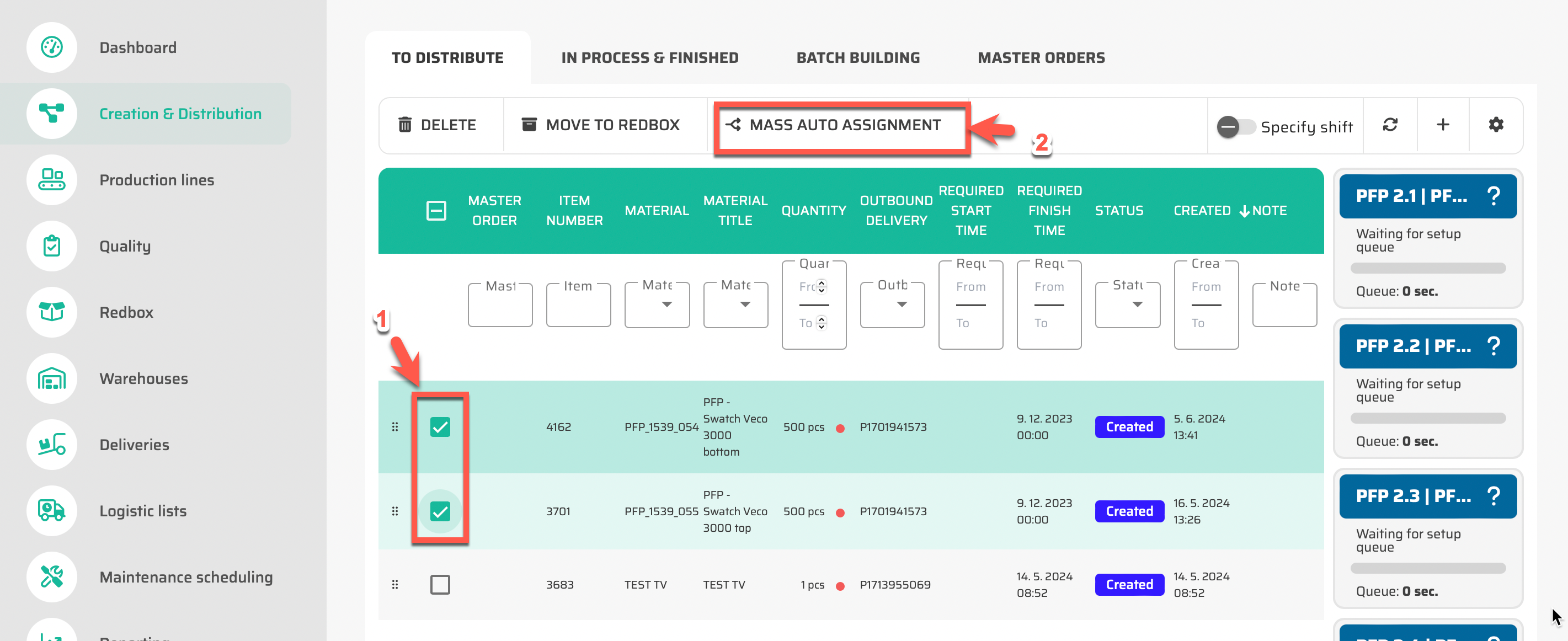

Mass assignment

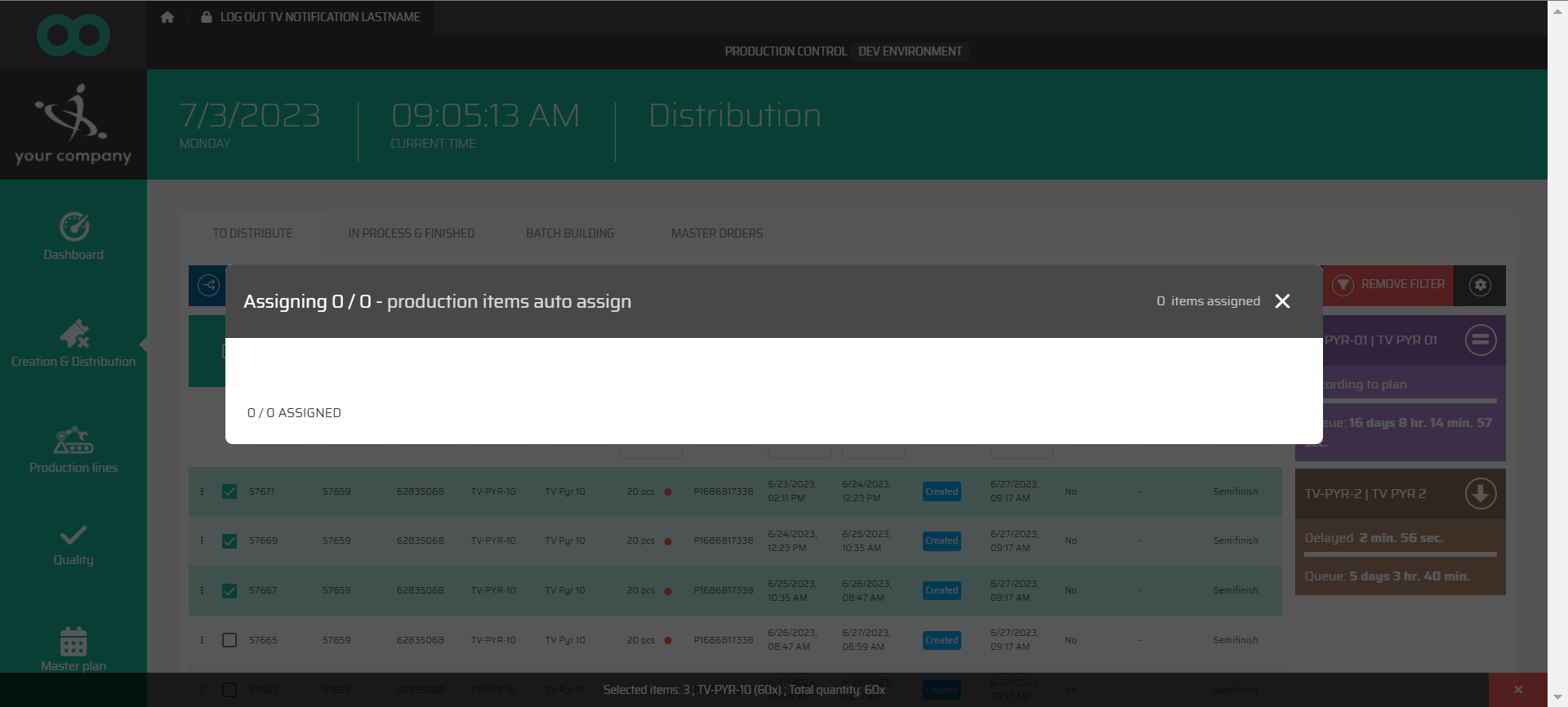

By selecting Production Items with checkboxes, the blue button “Mass auto assignment” appears on the upper bar.

By clicking on this button, the selected Production Items are automatically assigned to their default Production Lines and confirmation dialog is displayed.

Assignment dialog

During assigning process, the assigning dialog can appear. The design and possibilities of the assign dialog are based on these rules:

Parameter in main application settings: Simple Assign Process | Planning mode of the Production Line | Assignment process | Assign dialog type |

|---|---|---|---|

FALSE | sequence | Manual assignment | Full assign dialog |

FALSE | sequence | Mass auto assignment | Full Mass auto assign dialog |

FALSE | sequence | Auto assignment | no dialog |

FALSE | calendar, hybrid | Manual assignment | Full assign dialog |

FALSE | calendar, hybrid | Mass auto assignment | Mass auto assign dialog |

FALSE | calendar, hybrid | Auto assignment | no dialog |

TRUE | sequence | Manual assignment | |

TRUE | sequence | Mass auto assignment | |

TRUE | sequence | Auto assignment | no dialog |

TRUE | calendar, hybrid | Manual assignment | |

TRUE | calendar, hybrid | Mass auto assignment | |

TRUE | calendar, hybrid | Auto assignment | no dialog |

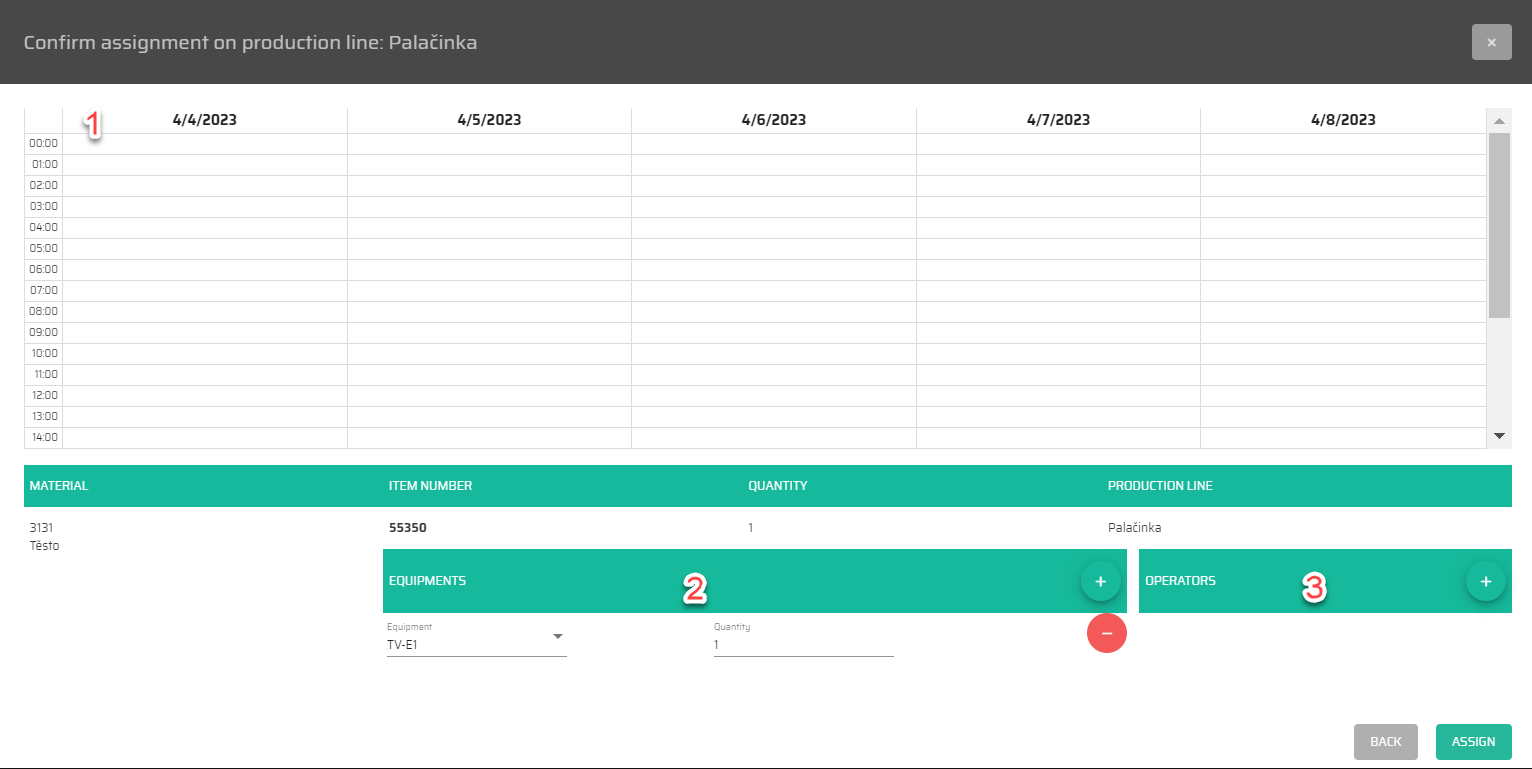

Full assign dialog

This type of assign dialog is the most complex one and contains the preview of the production queue.

Production plan of this Production Line

Special equipment

Specific operator

Standard Simple assign dialog

If the Simple assign dialog is activated in application settings, only confirmation about assigning process is displayed in the dialog.

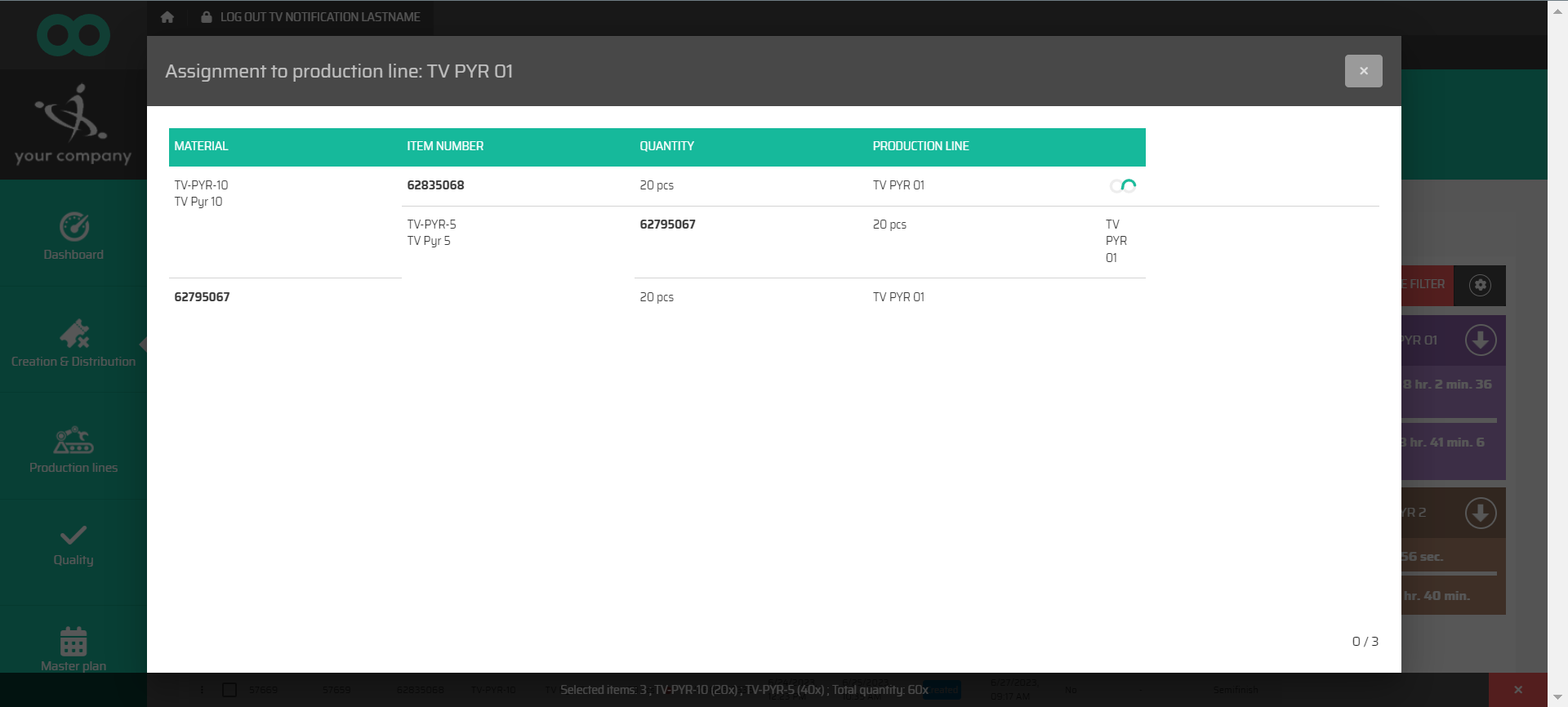

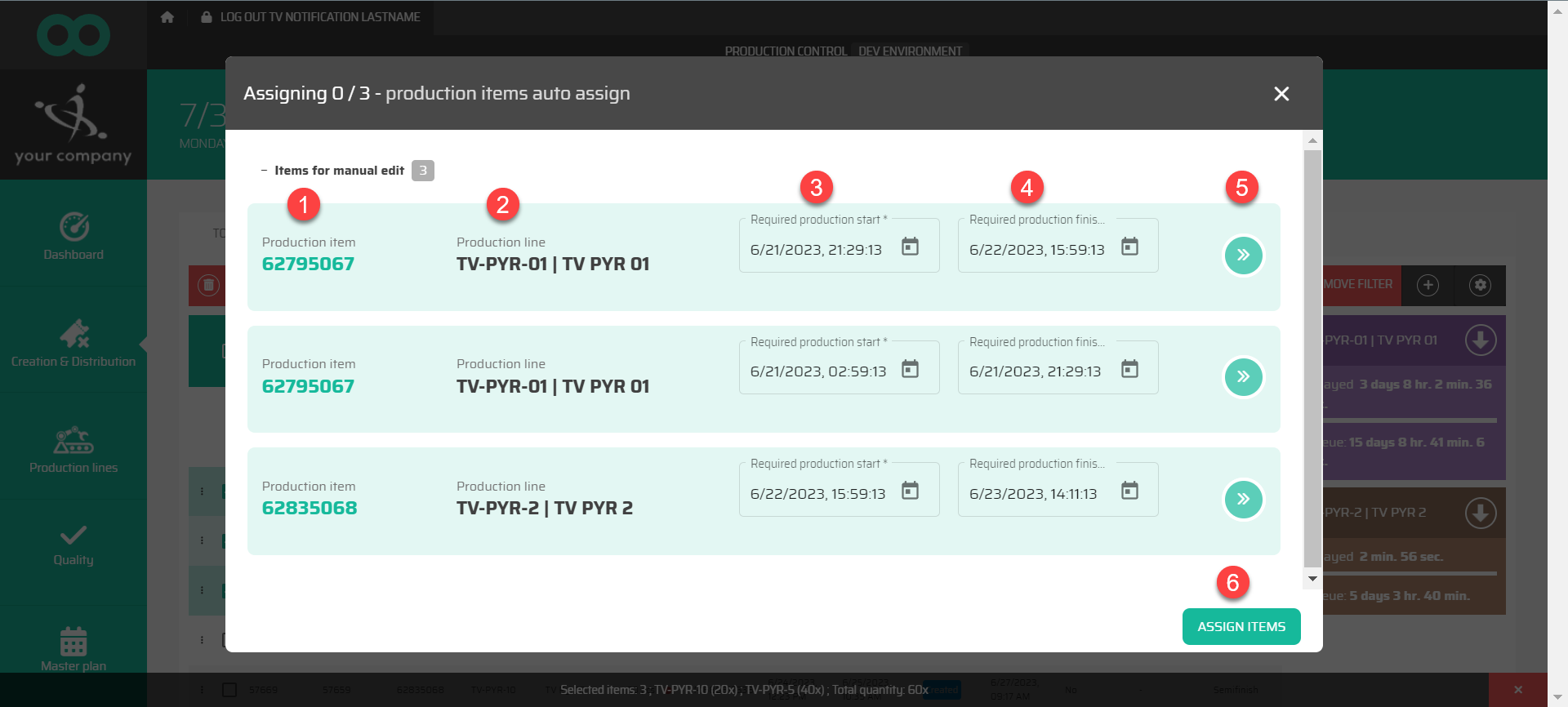

Full Mass auto assign dialog

This dialog display selected Production Items and their automatically selected Production lines.

Production Item

Automatically selected Production Line

Required production start

Required production finish

Status of the assignment

Confirming button

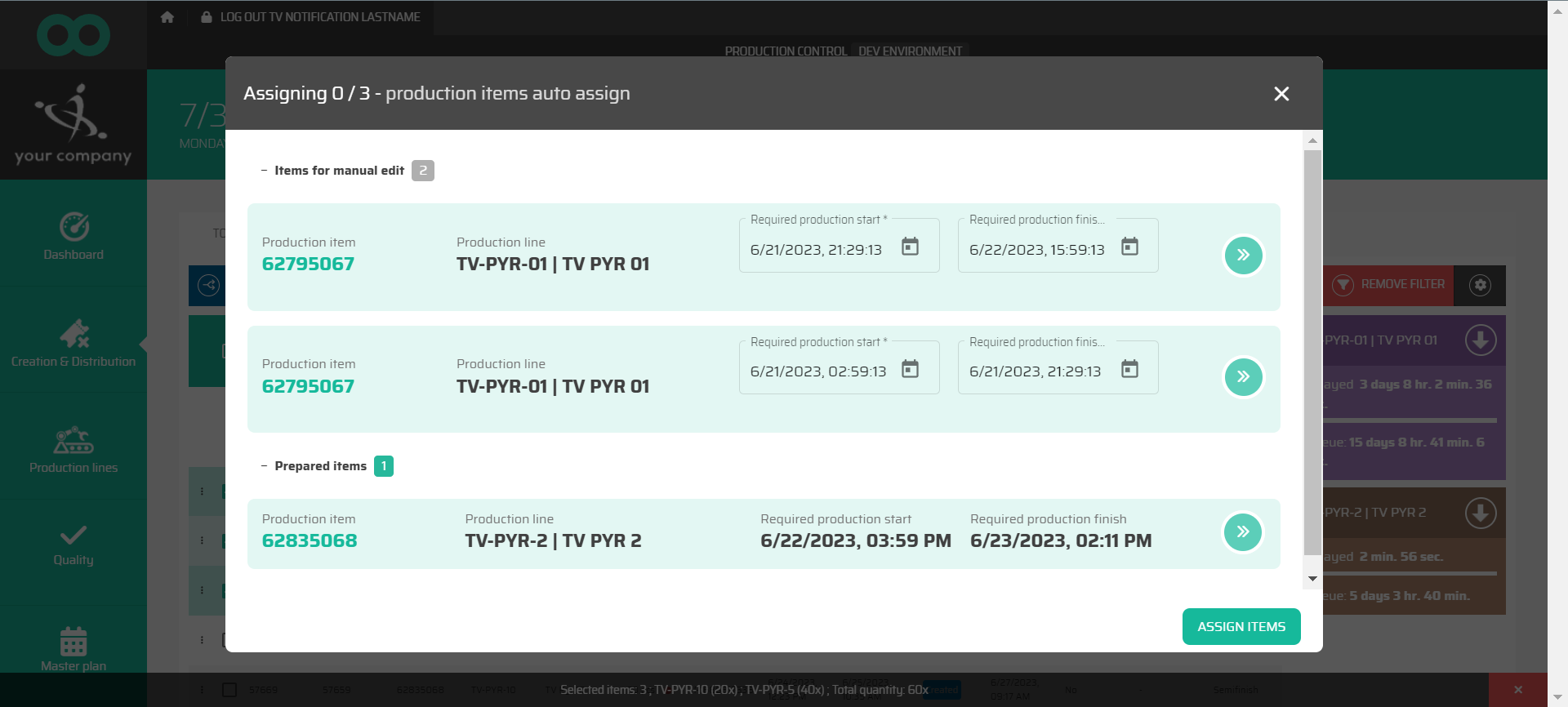

Mass auto assign dialog

This dialog display selected Production Items and their automatically selected Production lines. For Production lines that has calendar or hybrid planning mode is possible to manualy select/edit required start and finish time.

Production Item

Automatically selected Production Line

Required production start

Required production finish

Status of the assignment

Confirming button

Simple Mass auto assign dialog