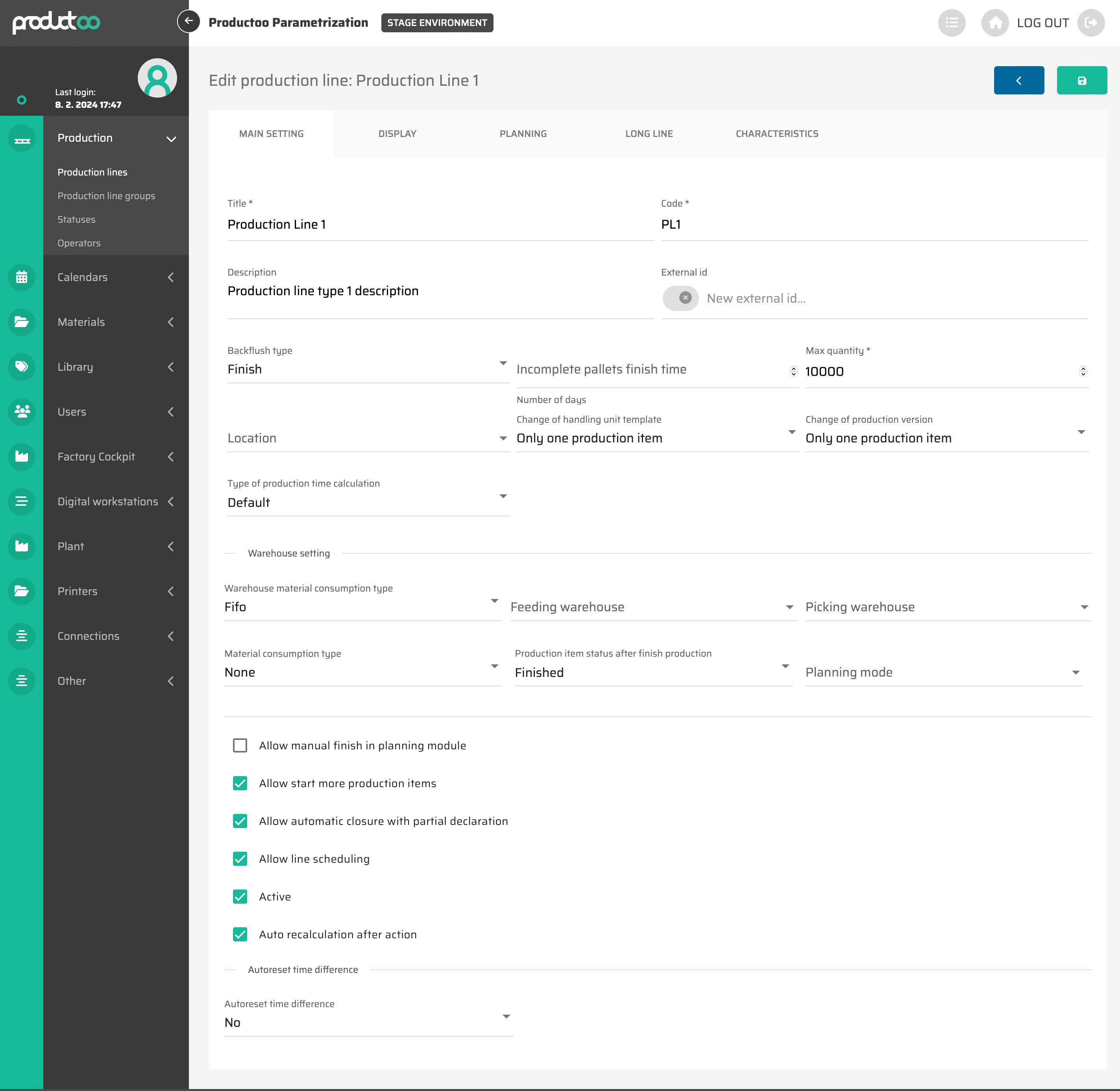

Production Lines - Main Settings

In the “Main Settings”, we primarily fill in the basic settings of Production Lines.

In the below table there are all parameters of the Production Line tab Main Settings with its description.

Parameter name | Limitations | Possible values | Description | DB field |

|---|---|---|---|---|

Title | 100 chars | free text | Title of the production line. | [PRODUCTION_LINE].[TITLE] |

Code | 50 chars | free text | Code of the production line. | [PRODUCTION_LINE].[CODE] |

Description | 255 chars | free text | Description of the production line. | [PRODUCTION_LINE].[DESCRIPTION] |

Backflush type | defined values |

|

| [PRODUCTION_LINE].[BACKFLUSH_TYPE] |

External ID | 100 chars | free text | External ID of the production line. | [PRODUCTION_LINE].[external_id] |

Incomplete pallets finish time | 0 or positive number | number of days |

| [PRODUCTION_LINE].[fin_incomp_pallets_time] |

Max quantity | 0 or positive number | Number |

| [PRODUCTION_LINE].[MAX_QUANTITY] |

Location | defined values | list of all locations | Selection of location of this production line. | [PRODUCTION_LINE_SETTING].[ID_LOCATION] |

Change of handling unit template | defined values |

|

| [PRODUCTION_LINE].[hand_unit_tmp_change_type] |

Change of production version | defined values |

|

| [PRODUCTION_LINE].[prod_version_change_type] |

Type of production time calculation | defined values |

| [PRODUCTION_LINE].[final_production_time_type] | |

Warehouse material consumption type | defined values |

|

| [PRODUCTION_LINE].[WARE_MATERIAL_CONSUMPTION_TYPE] |

Feeding Warehouse | defined values | list of all warehouses | The default warehouse from which materials are consumed by production. | [PRODUCTION_LINE].[ID_INPUT_WAREHOUSE] |

Picking Warehouse | defined values | list of all warehouses | The default warehouse to which manufactured materials are generated. | [PRODUCTION_LINE].[ID_OUTPUT_WAREHOUSE] |

Material consumption type | defined values |

|

| [PRODUCTION_LINE].[MATERIAL_CONSUMPTION_TYPE] |

Production item status after finish production | defined values | list of all production statuses | Defines a status which is assigned to production item after production declaration. | [PRODUCTION_LINE].[ID_STATUS_AFTER_PROD_FINISH] |

Planning mode | defined values |

| Defines whether the planning strategy for this line is sequence or fix time (calendar) of both options combined (hybrid). | [PRODUCTION_LINE].[planning_mode] |

Allow manual finish in planning module | checkbox | on / off | Allows you to declare the production of the currently processed Production Item on this line from the Production Control screen. | [PRODUCTION_LINE_SETTING].[MANUAL_FINISH] |

Allow start more production items | checkbox | on / off | It enables multiple Production Items to be processed on this line at one time. | [PRODUCTION_LINE].[ITEMSINPRODUCTION] |

Allow automatic closure with partial declaration | checkbox | on / off | If activated, in the partial declaration process, production is automatically completed when the required quantity of the Production Item is declared. | [PRODUCTION_LINE].[allow_automatic_closure] |

Allow line scheduling | checkbox | on / off | When the function is activated, it is possible to manually change the order of Production Items on the line from the line planning screen. | [PRODUCTION_LINE].[line_scheduling] |

Active | checkbox | on / off | Inactive lines are not displayed in other application modules except for Parameterization. Production orders cannot therefore be assigned to inactive lines. | [PRODUCTION_LINE].[active] |

Autoreset time difference | defined values |

| Defines the moment when the time differences of the production queue should be reset. Estimated production times are then set as scheduled and line delays are reset to zero.

| [PRODUCTION_LINE].[TIME_CHANGEOVER] |