Master orders

The Master Orders page provides an overview of all top-level Production Items that serve as the highest parent in a hierarchical structure of interconnected production orders. These items are essential for managing manufacturing processes that involve multiple levels of dependencies based on the Bill of Materials (BOM).

Concept of Master Orders

A Master Order represents a primary Production Item that does not have any parent item within the production structure. It is the root of the hierarchical tree formed when creating production items based on a BOM with linked items.

When a Production Item is generated using a BOM with linked items, the system automatically creates corresponding production items for each manufactured component in the required quantity. These production items are linked through a parent-child relationship, forming a tree structure that mirrors the BOM structure.

The Master Order is the highest parent in this hierarchy, ensuring that all related production items are structured and managed efficiently. The list displayed on the Master Orders page contains all Production Items that are at the top of their respective trees within the hierarchy of interconnected production orders.

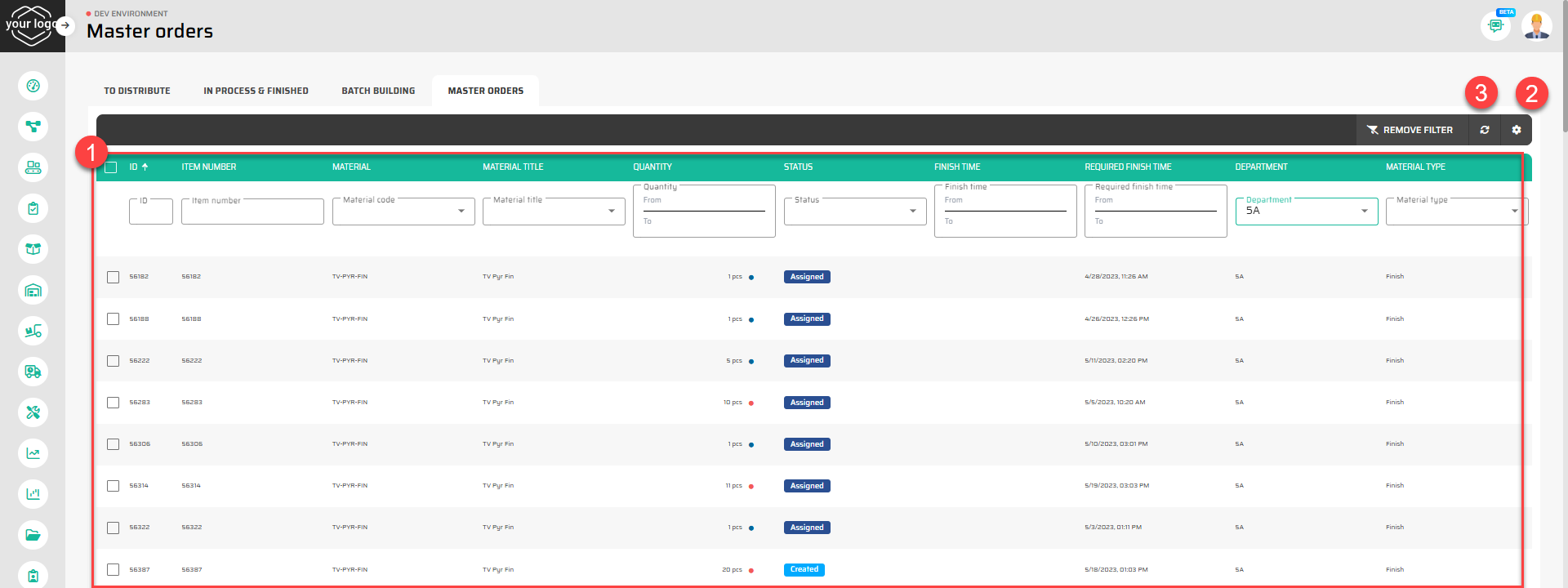

List of Master orders.

The button :Customize_Table: opens the Layout for this data table.

Column | Description | DB Field |

|---|---|---|

ID | Database ID. | [PRODUCTION_ITEM].[ID] |

Item Number | Unique Production Item Number. | [PRODUCTION_ITEM].[number] |

Material | Material Primary identificator. | [PRODUCTION_ITEM].[ID_MATERIAL] Relates to [MATERIAL].[ID] |

Material title | Material title. | |

Quantity | Total quantity of the production item. | [PRODUCTION_ITEM].[QUANTITY] |

Status | Production Item Status.* | [PRODUCTION_ITEM].[ID_STATUS] Relates to [STATUS].[ID] |

Finish Time | Time when this item was finished | [PRODUCTION_ITEM].[TIME_FINISH] |

Required Finish Time | Time when it is required to finish this item. | [PRODUCTION_ITEM].[TIME_REQUIRED_FINISH] |

Department | Identificator of company production department that manages this product. | [PRODUCTION_ITEM].[ID_MATERIAL] Relates to [MATERIAL].[ID] |

Material Type | Type of material |

Master Order Status Management

The status of a Master Order can be determined in two ways, depending on the global application Settings:

The Master Order undergoes production itself, meaning its status is updated based on its direct production status.

The Master Order acts as a "virtual" representative of the final product, and its status is automatically updated based on the statuses of its direct child production items.*

When a Master Order reaches the Finished status, the system sets the Finish Time for that order.

*Rules defining automatic changes of Master Order Status:

Master status | Rule |

|---|---|

Created | All direct childs = “created” |

Assigned | Direct childs in “created” or “redbox” at least 1 direct child in “assigned” |

In progress | Direct childs in “created” or “assigned” or “finished” or “redbox” at least 1 direct child in “in progress” |

Finished | All direct childs in “finished” |