Batch building

The batch building is a process of assembling a group of items or products that are similar or related in some way. It typically involves gathering together all the necessary components or materials needed to create the batch and then assembling them in a systematic way.

In manufacturing or production processes, batch building is often used to improve efficiency and reduce costs. Instead of producing items one at a time, products are made in batches, which can help reduce setup time and minimize material waste.

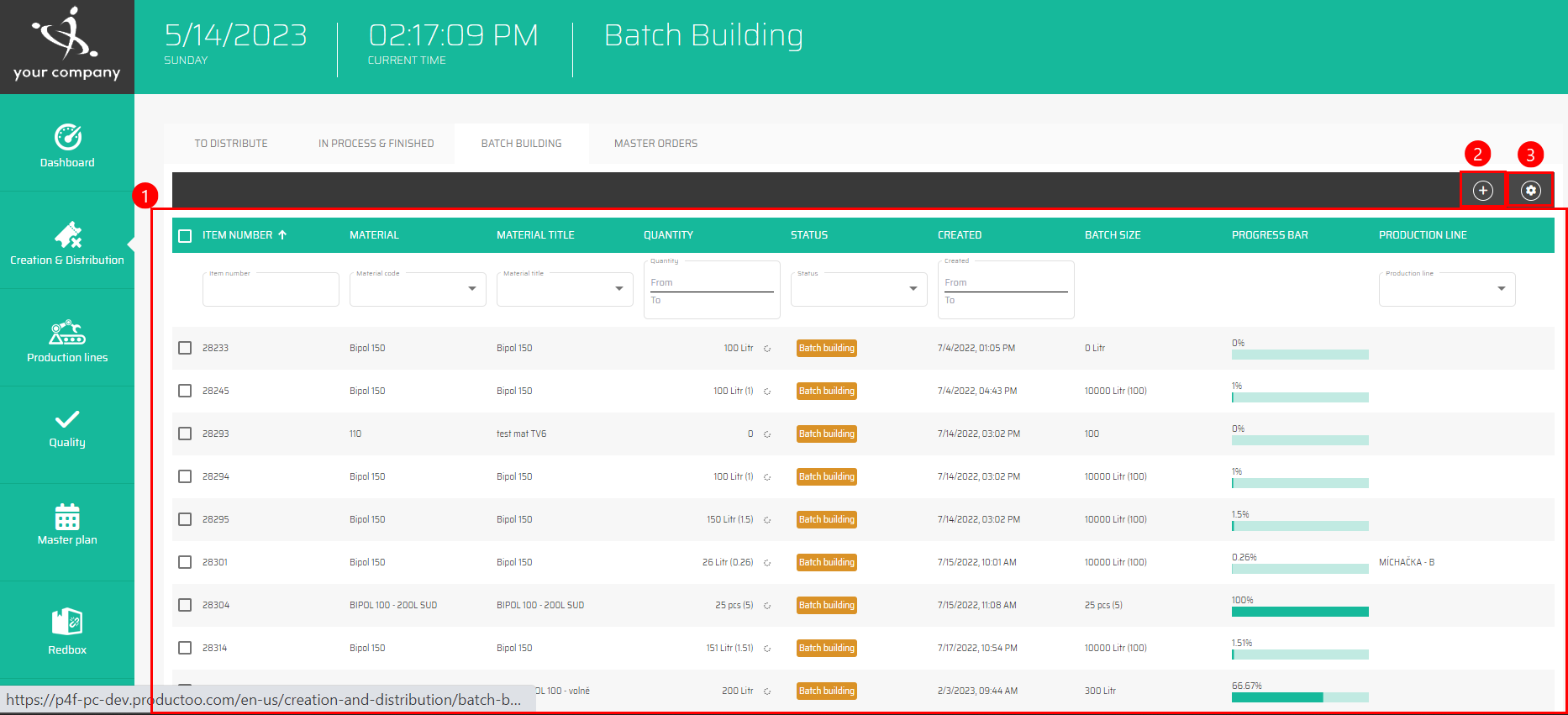

The screenshot below displays the parts of the tab:

The list of all production items in the status Batch building.

Button to create a new production item

The button opens the Layouts for this page, opens the Layouts for this specific page and you can find the same buttons across the entire Production control. This enables the user to personalize shown data in the table below.

The list of production lines can be filtered by all shown columns, which means by:

ID

Item number

Material

Material title

Quantity = Number of pieces currently.

Outbound delivery

Status

Created

Batch Size = The number of pieces that I need to stock up to start production.

Progress Bar = The status of the production batch in percent.

Production Line

Comment

The batch Batch building is set in the material parameterization.

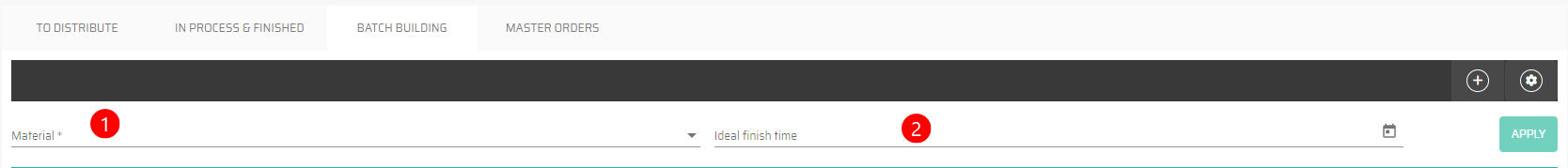

Creation of a new batch command with :Add_buttonPC_: :

In the table below you will find all attributes which are possible to insert into this dialog together with its description.

# | Parameter name | Limitations | Possible values | Description |

|---|---|---|---|---|

1 | Material* | Define value | The list of all available materials for the selection. | Material from which I want to create a batch. |

2 | Ideal finish time | DD/MM/YYYY, HH:MM:SS | Existing date 00:00:00 - 23:59-59 | The ideal time to fill the batch. |

Once a batch is assembled, it is moved as a single unit to distribution, where it is separated and distributed to the production line. The goal is to get the products or components to the appropriate location within the production process quickly and efficiently to keep the production line running smoothly.

The batch can be finished manually regardless of the quantity. This allows for customization and ensures quality standards are met, even for low production volumes.

After finishing production, there is an option to either divide the batch into individual orders or keep it intact. This decision may depend on factors such as inventory management, customer demands, or production efficiency.

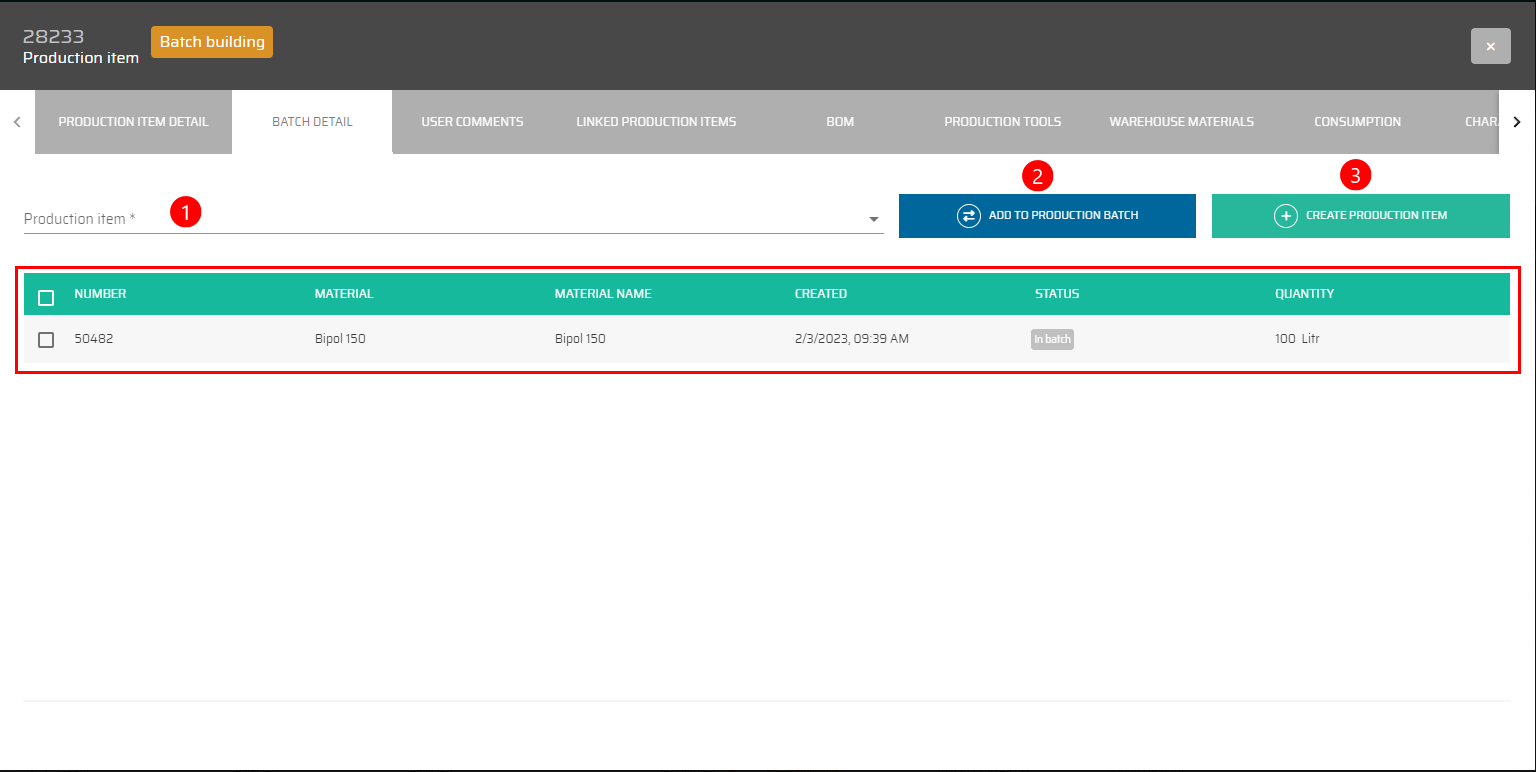

Batch building detail

Choose the specific production item

Choose another requirement for this material and add it manually with a :Add_productionBatch:.

Make a separate production order for this material with :Creation_productionItem:.

The list of production orders that the batch consists of.

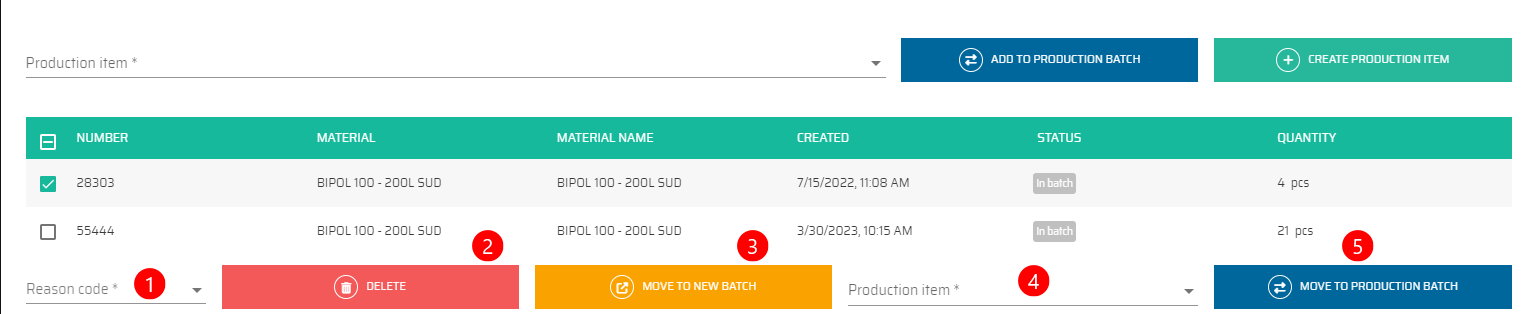

Specific items in Batch detail

Enter the reason code.

Option to :delete: the item.

Take an item from one group of things and put it in a different group with :move_to_new_batch:.

Enter the production item.

Add an item or product to a group of other items that are being manufactured together at the same time.

Production item detail shows the same information as described in To distribute.