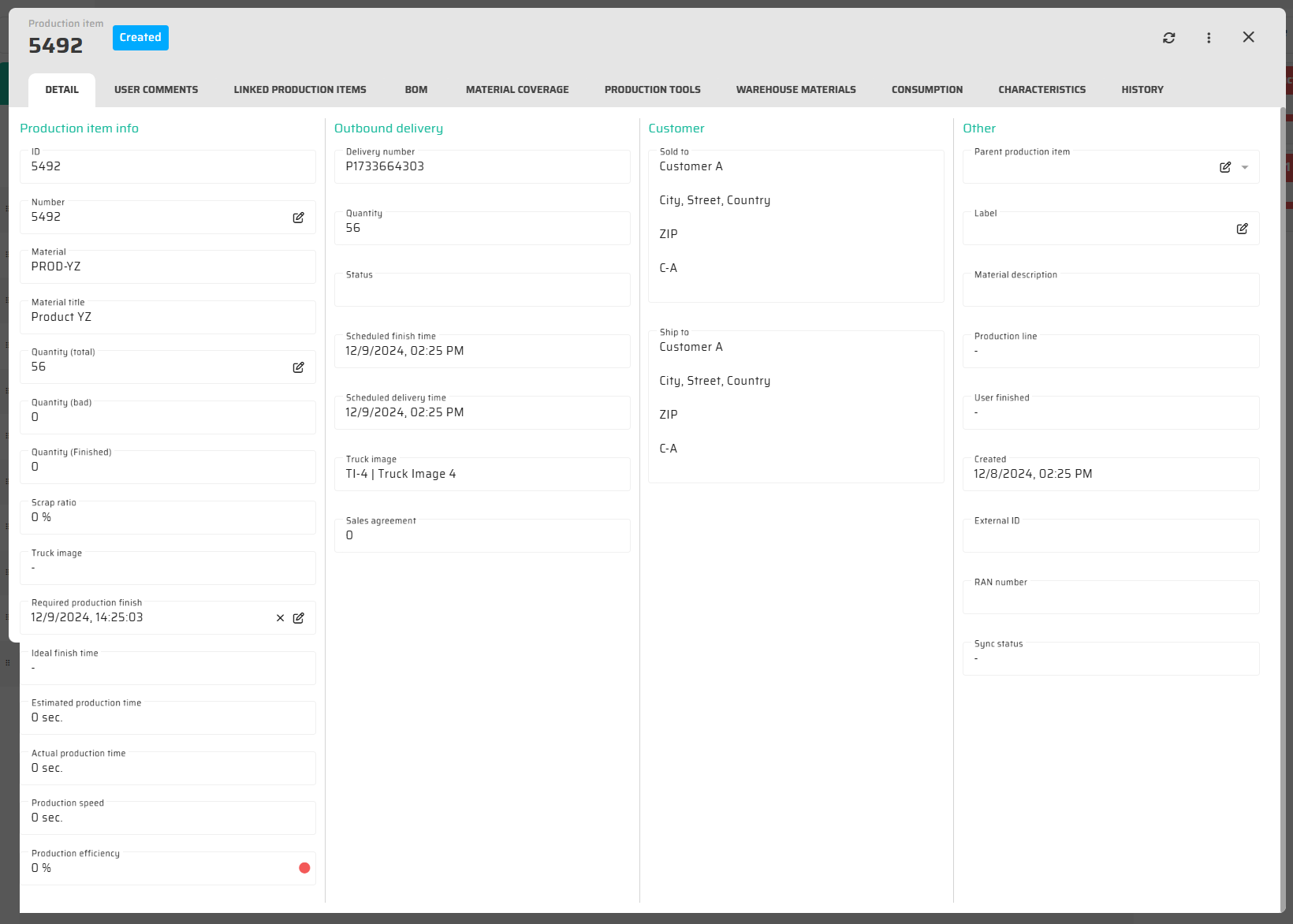

Production Item Dialog

The production line preview is comprised of multiple tabs, each providing access to different information or functionality relevant to the production process. Access to these tabs can be customized on an individual basis, ensuring that each team member has access to the information and tools they need to perform their job effectively.

Production Item Detail

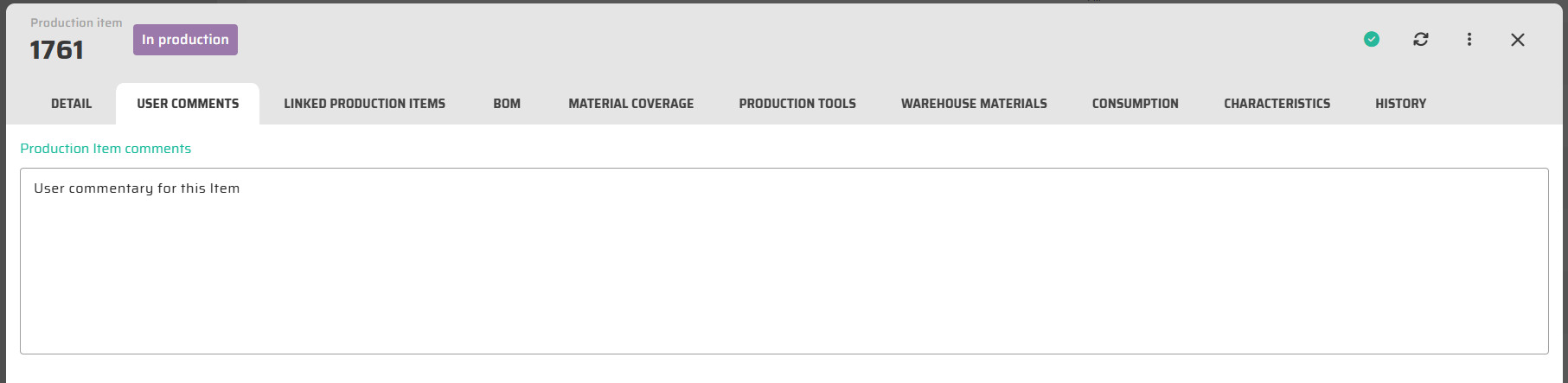

User Comments

Provides a way for authorized users to add notes or feedback related to a specific production item. These comments can include information such as quality control results, production issues, or suggestions for improvement.

Data Field: [PRODUCTION_ITEM].[comment]

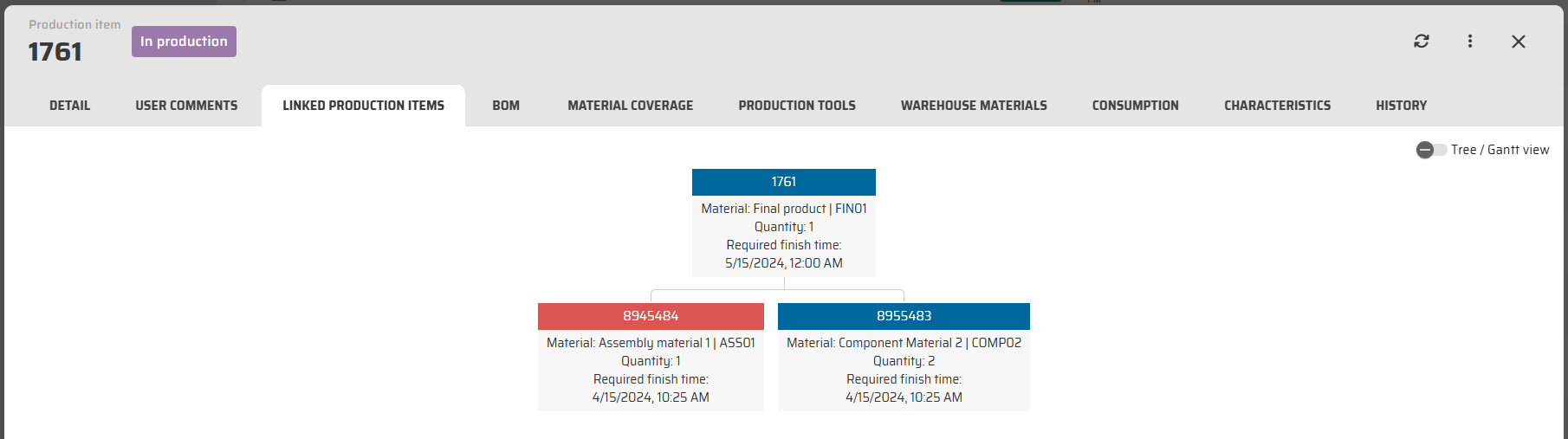

Linked production items

Production item that is associated or connected with another item in the production process, based on material BOM. This structure is generated when Production Item is created by BOM structure with linked items.

We can select these options in the selection bar 'Display option' by selection one of the two options:

Tree

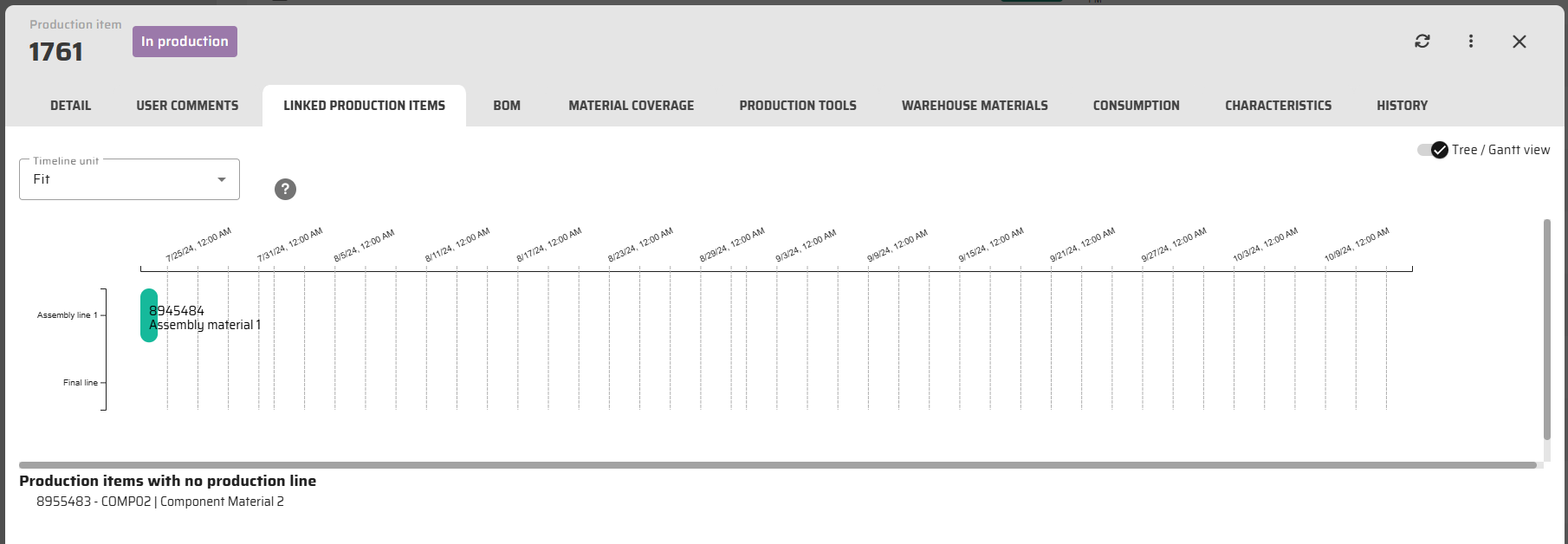

Gantt view

By selection ‘Tree’ we get this kind of view of the linke items:

Information in Graph.

Specific linked Production Items

By selection ‘Gantt view’ we get this kind of view:

Linked Production Items assigned to Production Lines visualized in unified timeline based on their planned production time.

Unassigned linked Production Items listed bellow graph

Data structured based on [PRODUCTION_ITEM].[ID_PARENT]

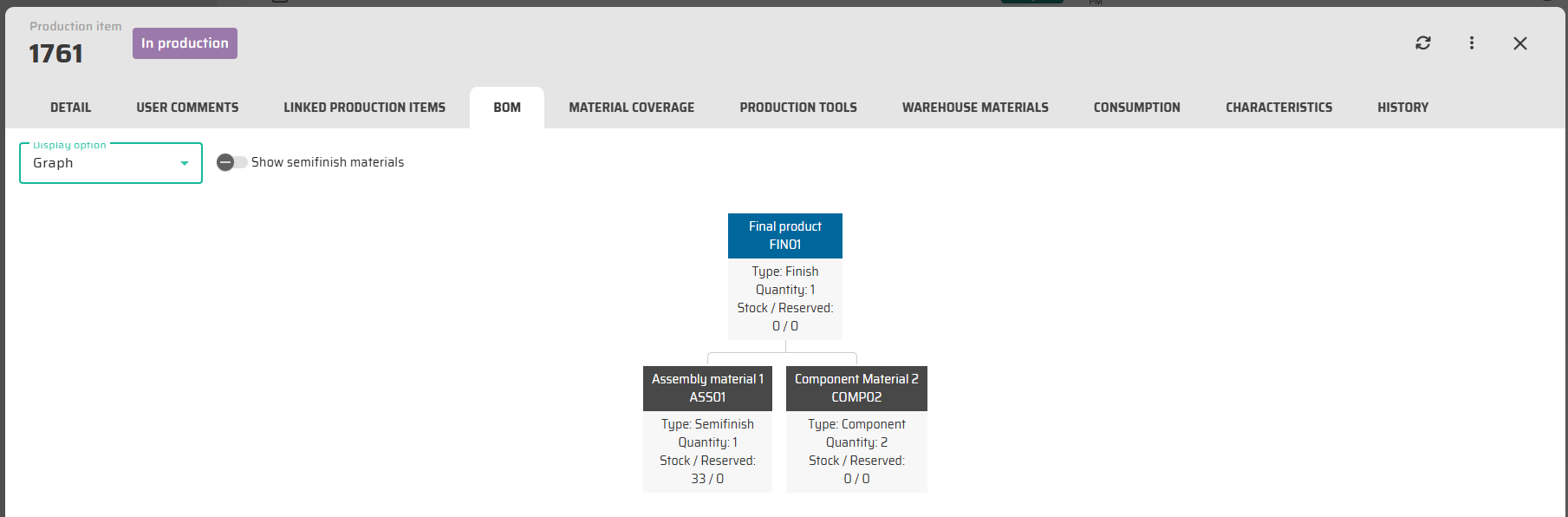

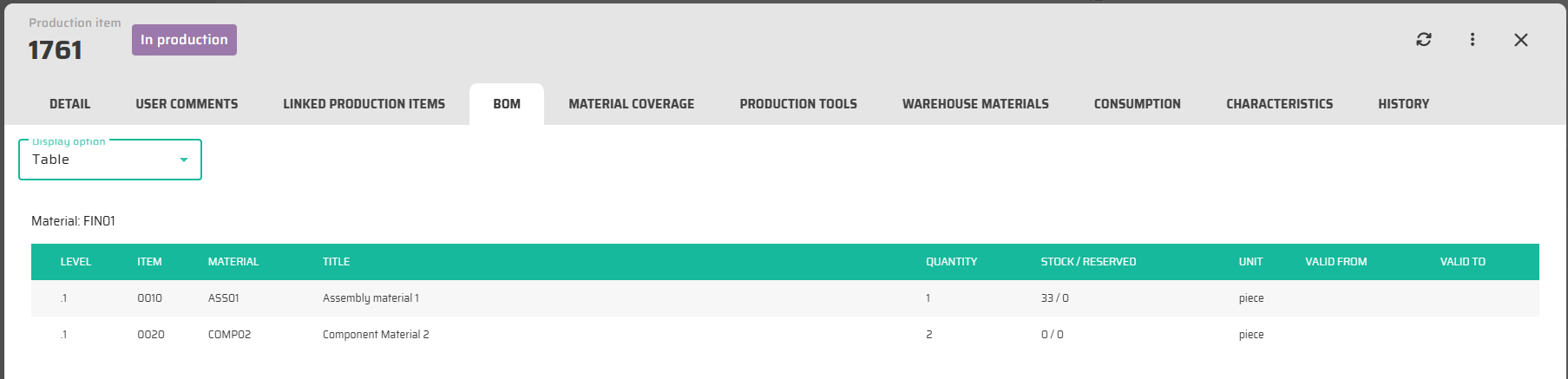

BOM

In the tab BOM of the produciton item detail, we can view this tab by two ways. We can select these options in the selection bar 'Display option' by selection one of the two options:

Graph

Table

By selection ‘Graph’ we get this kidn of view of the BOM:

Information in Graph.

Specific materials and their needed quantities

Possibility to display also deeper structures of BOM

By selection ‘Table’ we get this kidn of view of the BOM:

Information in table

Specific materials

Data structured based on [MATERIAL_BOM] table.

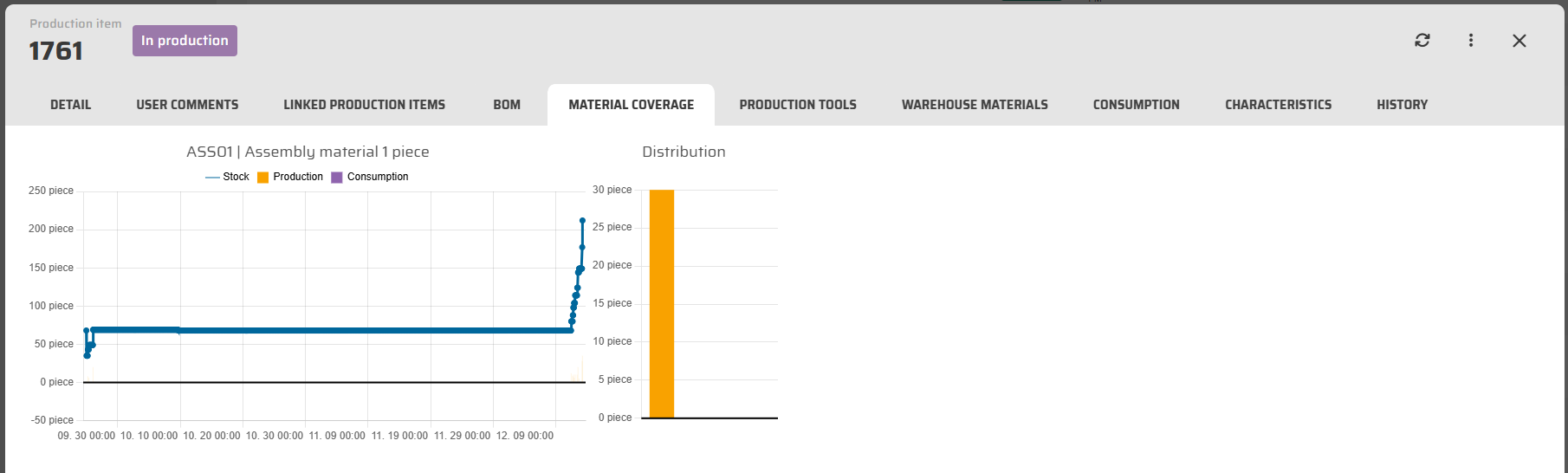

Material Coverage

This tab display calculated future stock levels of Materials needed for production of this Production Item based on Material BOM structure.

Data structured based on [VIEW_MATERIAL_COV_QUANTITIES_CONJUNCTION] table.

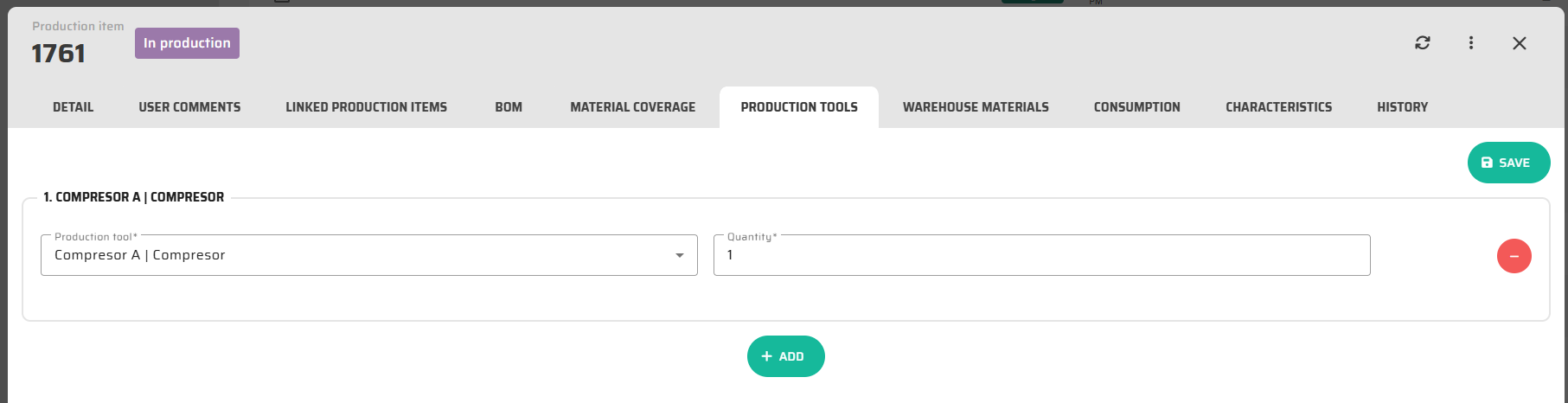

Production Tools

This tab display list of special production tools necessary for production of this item and their quantities.

Operational Buttons:

:Add: - To add a new equipment

:minus_delete: - to delete a row with the equipment

Data structured based on [PRODUCTION_ITEM_EQUIPMENT] table.

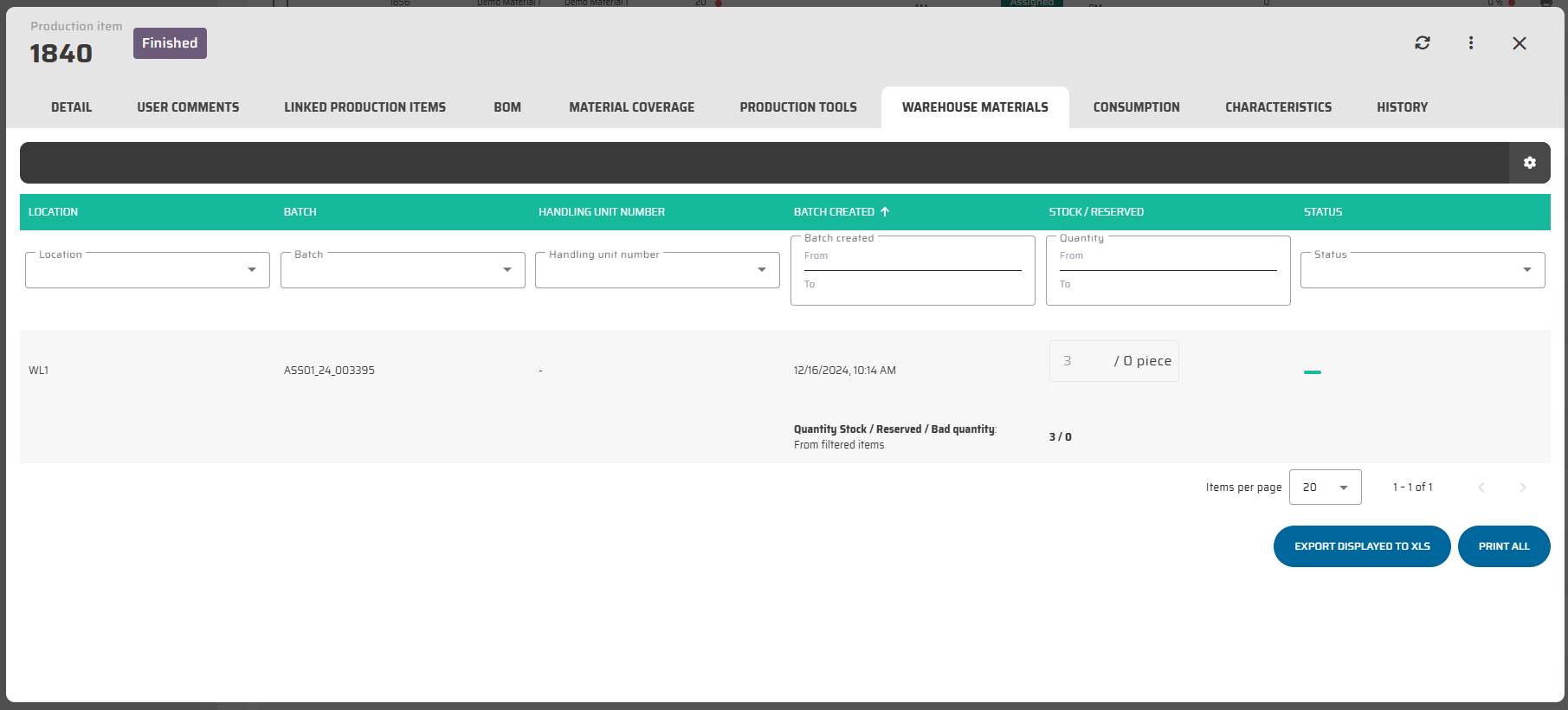

Warehouse Materials

This tab lists all Warehouse Materials created by this Production Item.

Warehouse material can be sorted by these data:

ID

Location

Batch

Batch created

Stock/reserved

quantity (bad)

Status

On the warehouse material detail we can see:

List of warehouse items.

The button :Customize_Table: opens the Layout for this data table.

With the button :Export: the software will generate an Excel file containing all the data that is currently being displayed on your screen. This can be useful if you need to analyze or manipulate the data in Excel or if you need to share the data with others who do not have access to the software you are using.

Print all data with the button :Printall:

Data structured based on [WAREHOUSE_MATERIAL_MOVEMENT] table.

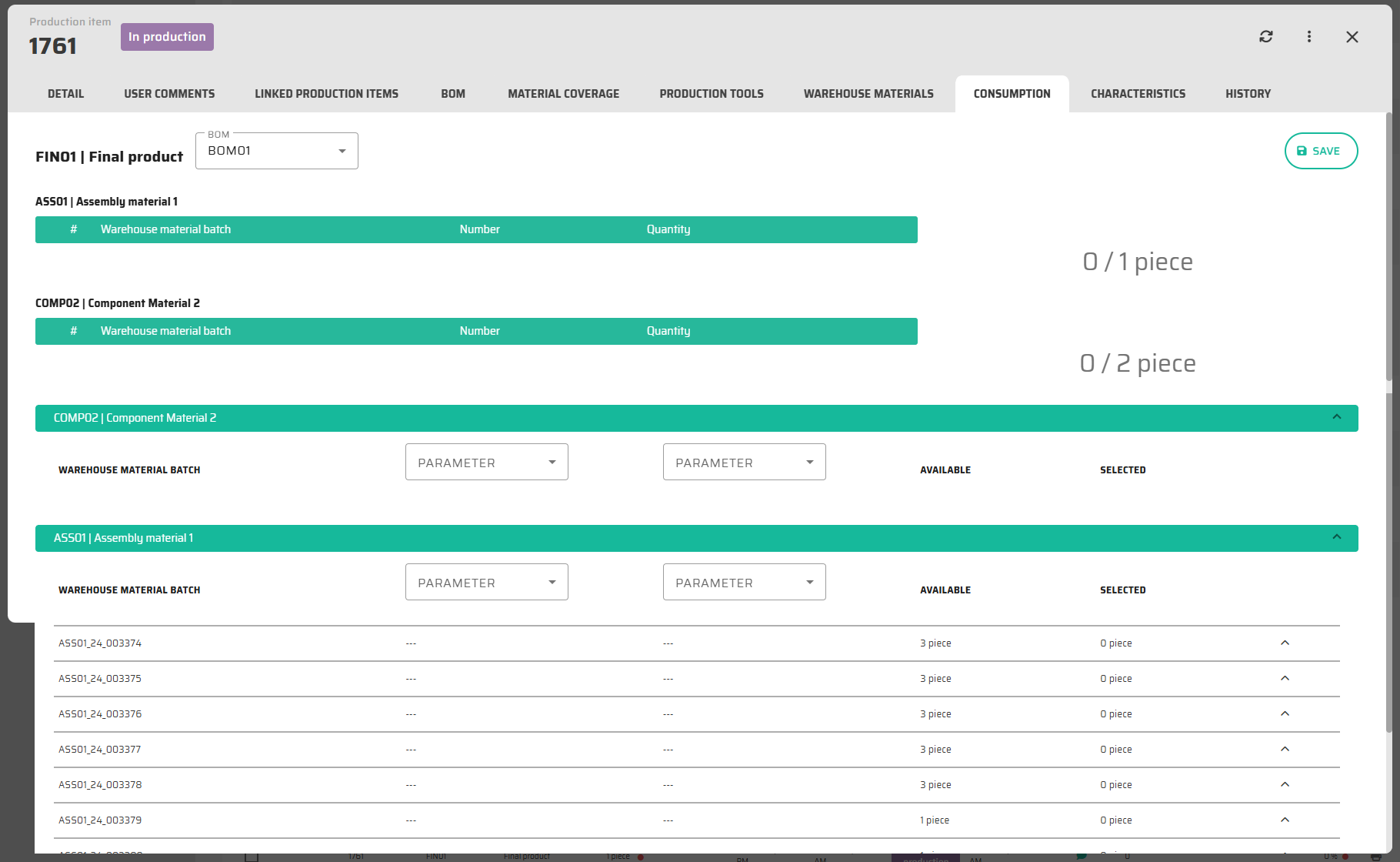

Consumption

This tab enables to select specific Warehouse Materials from BOM that should be consumed by production of this Production Item.

Data based on table [PRODUCTION_ITEM_RECIPE]

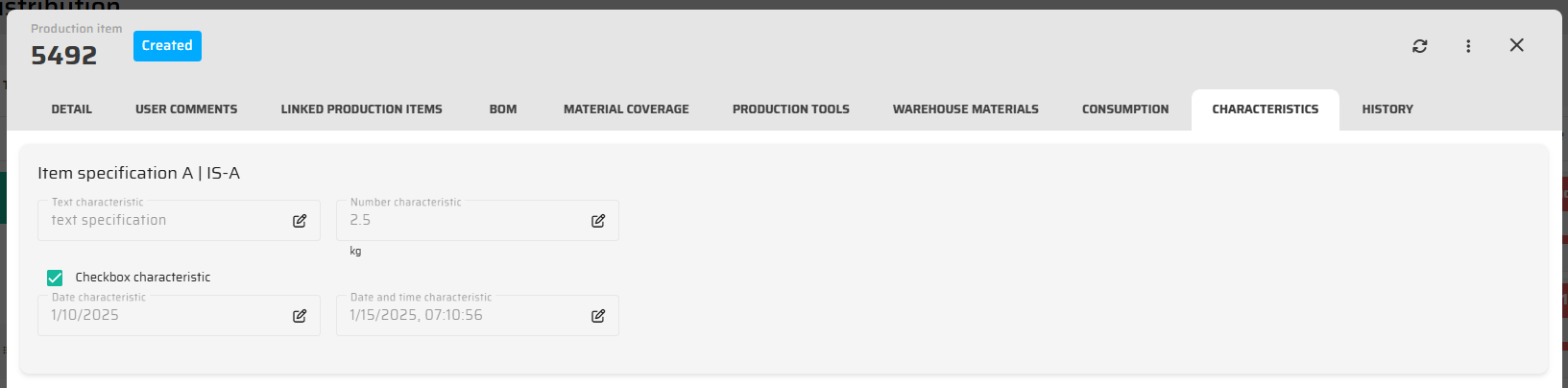

Characteristics

Characteristic is a universal value that is attached to some item and can be also shared with other entities. For example Material Characteristic can be automatically duplicated to its Production Item characteristics during its creation to provide operators and other users with some additional data general for this material, and simultaneously some characteristics can be specific to this Production Item.

Data based on table [CHARACTERISTICS_DATA] where

[PRODUCTION_ITEM].[ID] = [CHARACTERISTICS_DATA].[ENTITY_CODE]

and [CHARACTERISTICS_DATA].[ID_ENTITY] = 1

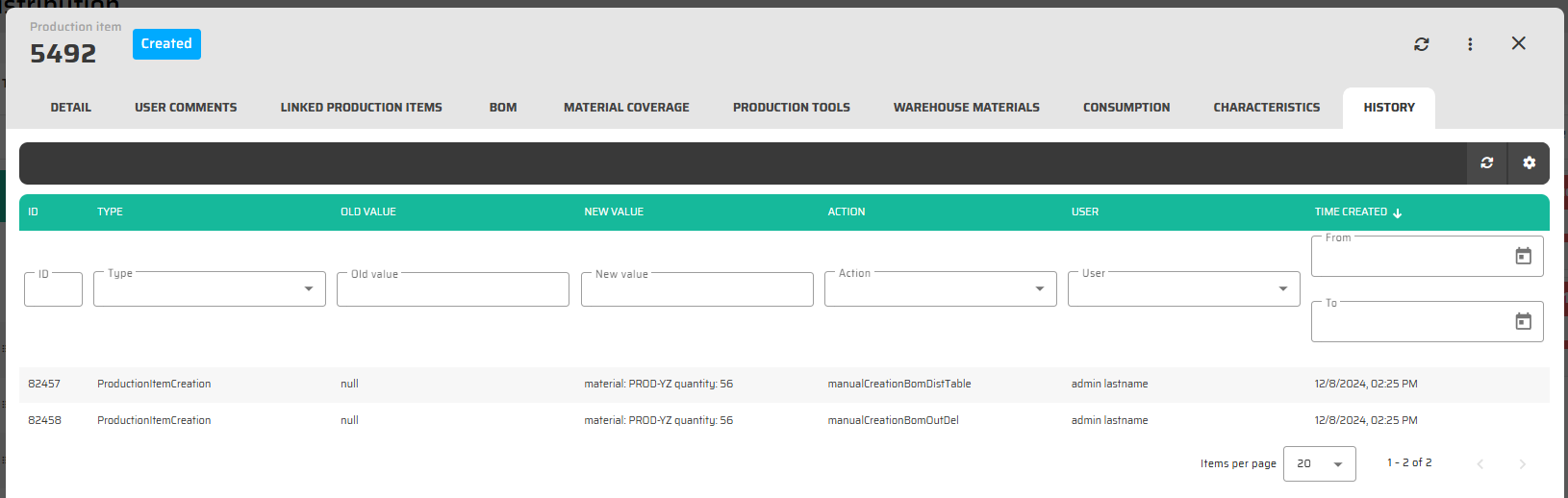

History

Represents a complete history of actions done with this Production Item from its creation.

Data based on table [CHANGE_EVENT] where

[PRODUCTION_ITEM].[ID] = [CHANGE_EVENT].[ENTITY_ID]

and [CHANGE_EVENT].[ENTITY_NAME] = 'ProductionItem'

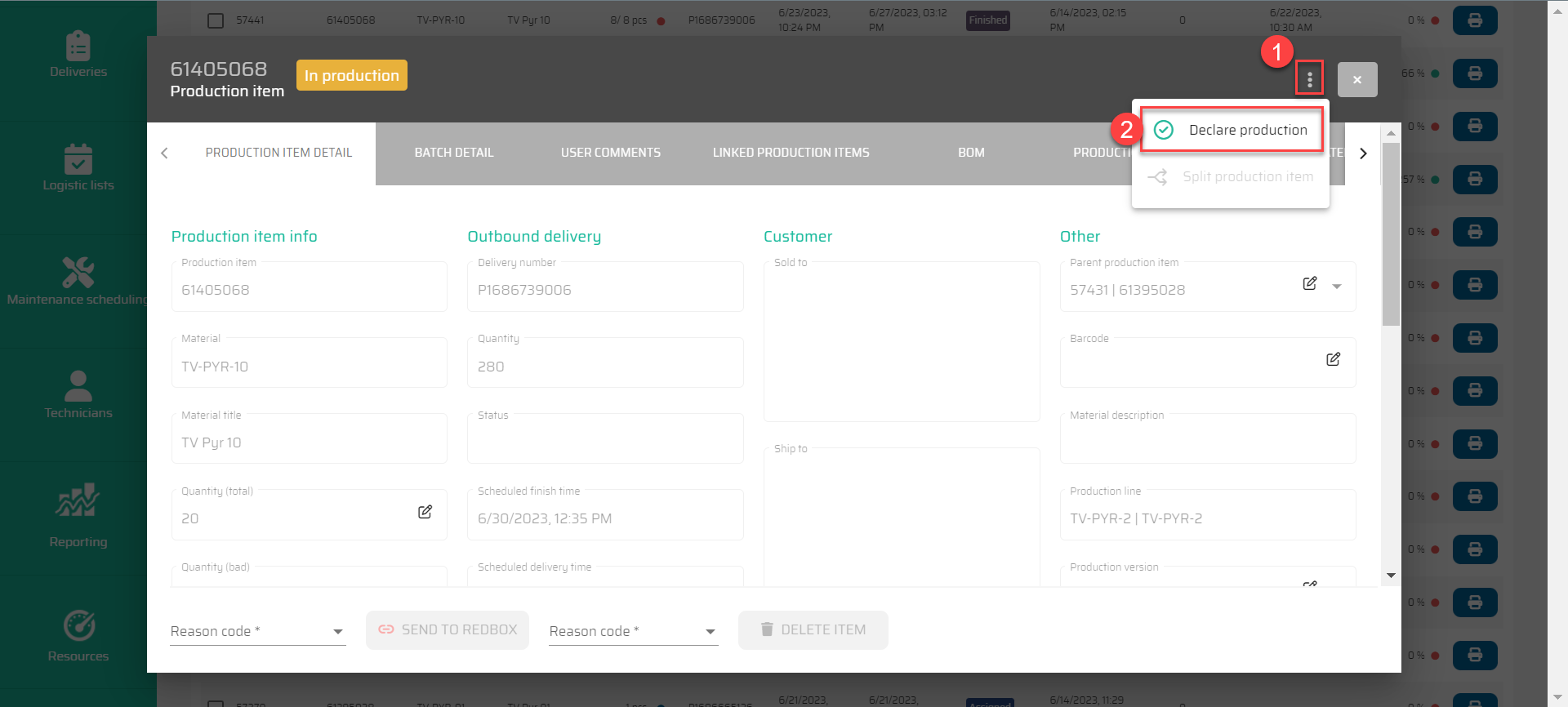

Declaration from planning module

If the parameter "Allow manual finish in planning module" is set in the settings of the production line where the given Production item is assigned, a menu will appear in the upper right corner of the dialog. Here it is possible to declare the production of this Production Item at the moment when its production has already started. A declaration made in this way will end production of the item in exactly the condition and quantity in which it is currently found. Therefore, if an incomplete quantity was declared, it is necessary to count on the fact that exactly such a quantity will be stored for the item without the possibility of reproducing it within this Production Item.

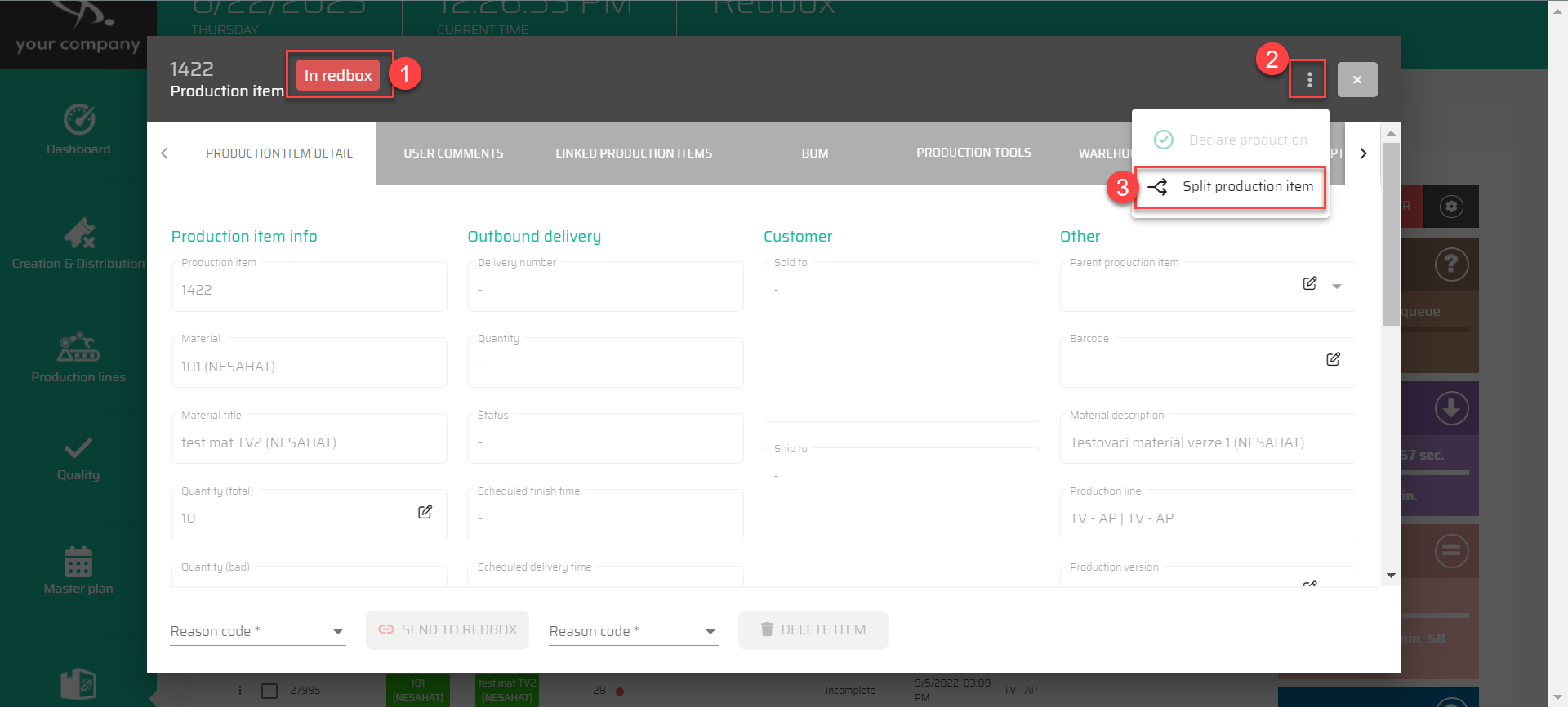

Split Production Item

If the Production Item is in Redbox (including Incomplete), a "Split Production Item" button will appear in the upper right corner of the dialog.

Pressing the button causes Production Item to divide into two separate Production Items and the following situations can occur:

A quantity has already been declared for the Production Item (most often when in Incomplete). In that case, the already declared quantity will be placed in one Production Item and its declaration will be made immediately - i.e. the declared quantity will be finished. The remaining (undeclared) quantity will be in the second PI and will still be in the redbox.

If no quantities have been declared yet, the Production Item will be split equally into 2 and both will still be in the redbox.

All properties of the Production Item are preserved, including the BOM. If this Production Item has linked sub-Production Items under it according to the BOM, these sub-items are also divided proportionally.