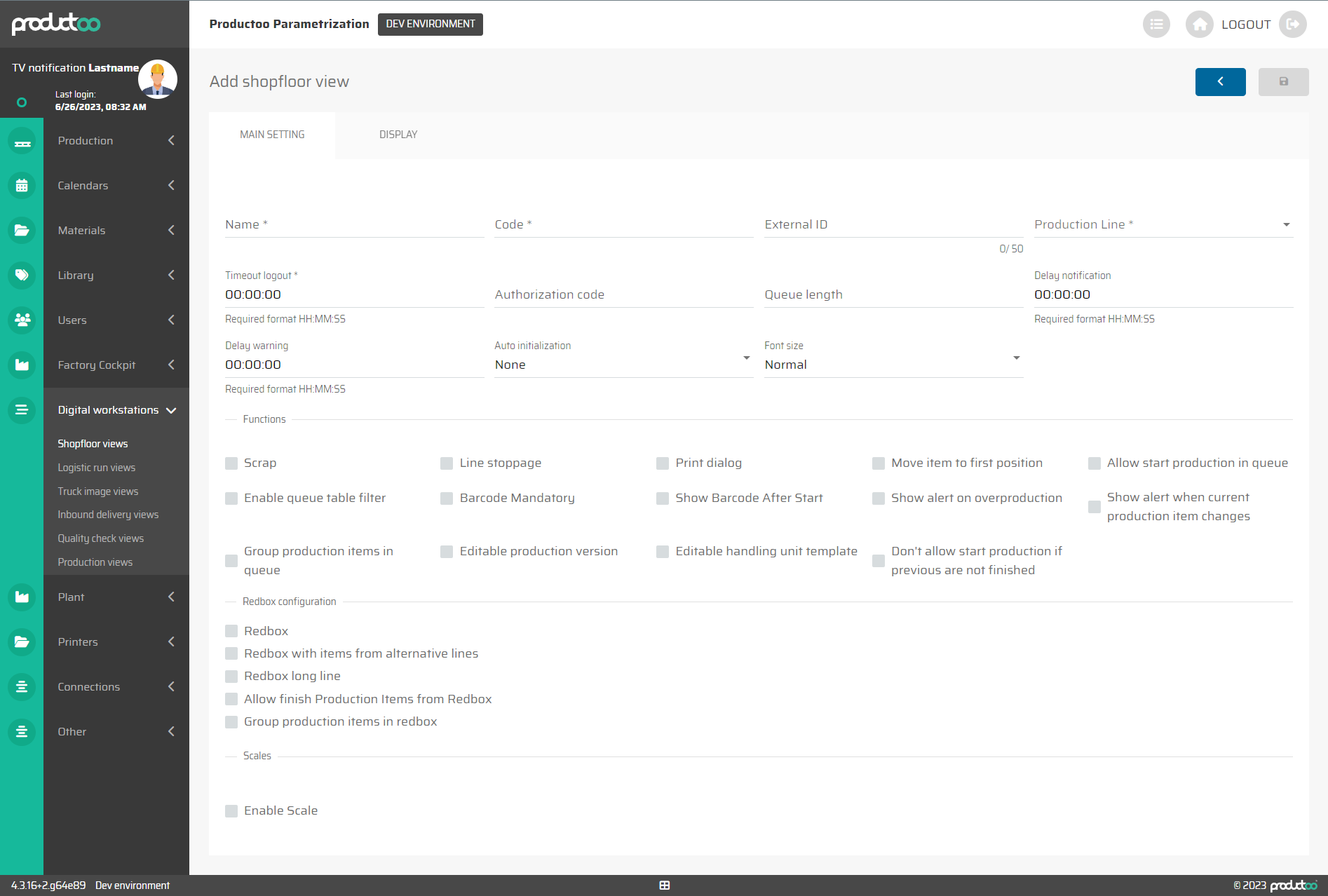

Main setting - Shopfloor View

In the “Main Settings”, we primarily fill in the basic settings of the Shopfloor view.

In the below table there are all parameters of the Shopfloor view tab Main Settings with its description.

Parameter name | Limitations | Possible values | Description |

|---|---|---|---|

Name | 100 chars | Free text | Name of the Shopfloor view. |

Code | 50 chars | Free text | Code of the Shopfloor view. |

External ID | 50 chars | Free text | Another possible identificator of this declaration screen - can be used for external system comunication. |

Production Line | defined values | All available production lines for selection | Selection of all available production line which the shopfloor view is gointto be assigned on. If global application setting “Shopfloor View Automatic Creation” is active, this field is prefilled with Production Line to which it was automatically created for. |

Timeout logout | HH:MM:SS | 00:00:00 - 23:59:59 | Automatic logout feature that ensures that users are logged out of the screen after a certain period of inactivity. With a value of 00:00:00 (the default), automatic logout will never occur. |

Authorization code | Free text | PIN code for this declaration screen. PIN can be mandatory for login to this Declaration screen or used for approval of some actions. | |

Queue length | 0 or positive number | Number | Maximum displayable number of Production Items in the production queue. With a value 0 (default) there is no limitation. |

Delay notification | HH:MM:SS | 00:00:00 - 23:59:59 | If the production delay on the production line exceeds this value, the background of the screen will change its color to orange. |

Delay warning | HH:MM:SS | 00:00:00 - 23:59:59 | If the production delay on the production line exceeds this value, the background of the screen will change its color to red. |

Auto initialization | defined values |

| This parameter activates the automatic production start function after the declaration of the previous Production Item based on the following rules:

|

Font size - selection bar | defined values |

| Defines the size at which important information should be displayed on the Shopfloor View screen.

|

Scrap | checkbox | on / off | Allows to work with Scrap on the screen - to report scrap from production and display its reported quantity. If this option is disabled, the report scrap button will be visible but inactive. |

Line stoppage | checkbox | on / off | Allows to report line stoppage from this declaration screen. |

Print dialog | checkbox | on / off | Active: after pressing the "Print" button, a dialog box is displayed to the operator with options for editing some values of the printed label. |

Move item to first position | checkbox | on / off | Allows the operator to move Production Items to the first position in the production queue. This action bypasses the production plan and the operator himself can determine the order of production orders in the queue. |

Allow start production in queue | checkbox | on / off | A button will appear in the production queue allowing to start the production of the Production Item even if it is not in the first position in the production queue.

|

Enable queue table filter | checkbox | on / off | Enables the ability to filter the production queue on this declaration screen. The filter highlights the searched items in the list. |

Barcode Mandatory | checkbox | on / off | When declaring production, writing/scanning a barcode is required. |

Show Barcode After Start | checkbox | on / off | When production of a Production Item starts, its barcode is displayed. |

Show alert on overproduction | checkbox | on / off | Displays a dialog warning if more than the requested quantity is declared. |

Show alert when curent production item changes | checkbox | on / off | Displays a dialog warning if curent Production Item is changed from other screen (for example queue change or sending PI to Redbox from Production Control). |

Group production items in queue | checkbox | on / off | Enables grouping of production items according to changeover in the production queue. |

Editable production version | checkbox | on / off | If information about the Production Version of the active Production Item is displayed, it is possible to edit it. |

Editable handling unit template | checkbox | on / off | If information about the Handling Unit Template of the active Production Item is displayed, it is possible to edit it. |

Don’t allow start production if previous are not finished | checkbox | on / off | The system includes a feature that ensures that production of a Production Item cannot be started until its previous item, as defined by the linked Production Items in the BOM structure, has been completed. This ensures that production can only begin once all necessary production operations and sub-assemblies have already been completed. |

Redbox | checkbox | on / off | Shows a bookmark with Redbox. This tab contains the Production Items that were sent to Redbox from this particular production line. |

Redbox with items from alternative lines | checkbox | on / off | Shows a tab with Redbox from alternate lines. All production items that can be processed on this production line and have been sent to Redbox from another production line are located here. |

Redbox long line | checkbox | on / off | Shows a bookmark with Redbox within a long line. All production items that have been sent to Redbox from this line and the lines following in the long line chain hierarchy. |

Allow finish Production Items from Redbox | checkbox | on / off | Allows you to declare a Production Item directly from Redbox - displays a button for declaring from redbox. |

Group production items in redbox | checkbox | on / off | Enables grouping of production items according to material in the Redbox. |

Enable Scale | checkbox | on / off | Activates the possibility of connecting the declaration screen to a scale, which can project the measured weight directly onto the declaration screen. |

Scale WS Channel | 50 chars | Free text | Technical parameter for connecting the measuring device to the screen. |