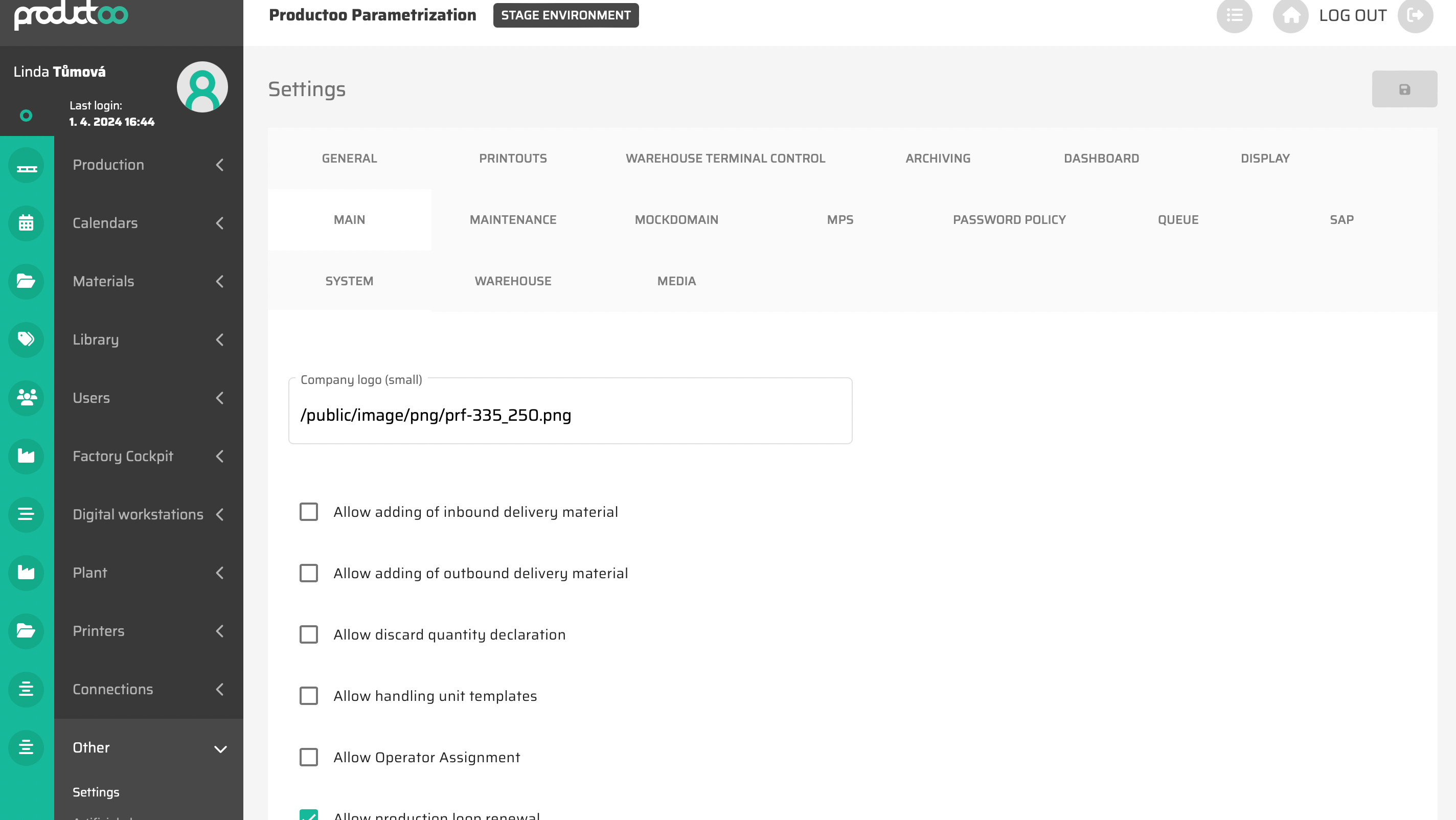

Main

In the below table there are all parameters of the settings, tab Main with its description.

Parameter name | Limitations | Possible values | Description |

|---|---|---|---|

Allow adding of inbound delivery material | Checkbox | On/Off | It will allow additional items to be added to an already created Inbound Delivery. |

Allow adding of outbound delivery material | Checkbox | On/Off | It will allow additional items to be added to an already created Outbound Delivery. |

Allow handling unit templates | Checkbox | On/Off | Enables the Handling Unit Templates functionality. |

Allow Operator Assignment | Checkbox | On/Off | During the process of assigning items to production, it will also make it possible to select a specific operator who should be present for this item. |

Allow production loop renewal | Checkbox | On/Off |

|

Allow Production Tools | Checkbox | On/Off | Enables the Production Tools functionality - production item can be created only with specific tools, based on Material Parametrization. |

Allow Production Versions | Checkbox | On/Off | Enables the Production Version functionality. |

Allows to exceed maximum production item quantity at shopfloor declaration | Checkbox | On/Off | It will make it possible to declare a larger quantity in production than was planned. |

Automatic preparation of reserved Outbound delivery materials | Checkbox | On/Off | Enables the function of automatic preparation of reserved items for dispatch. |

Deliveries - Allow confirmation alert for material handling unit change | Checkbox | On/Off | If activated, a notification is displayed every time the user changes the Handling Unit Template within an outbound order. |

Display invalid user authorization message | Checkbox | On/Off | If enabled, a warning is displayed when an unauthorized operation is attempted. |

Enable maintenance order assignment to myself on maintenance shopfloor view | Checkbox | On/Off | Allows user to assign a maintenance order to himself on the Maintenance Shopfloor View. |

Inbound Delivery autoclose when quantity is fully received | Checkbox | On/Off | Automatically close Inbound Delivery if all items are received. |

Is material group for Material required | Checkbox | On/Off | Defines whether it is mandatory to define a Material Group for a material. |

Is warehouse for Material required | Checkbox | On/Off | Defines whether it is mandatory to define a Warehouse for a material. |

More items to one place | Checkbox | On/Off | Allows more than one warehouse item to be placed per warehouse location. |

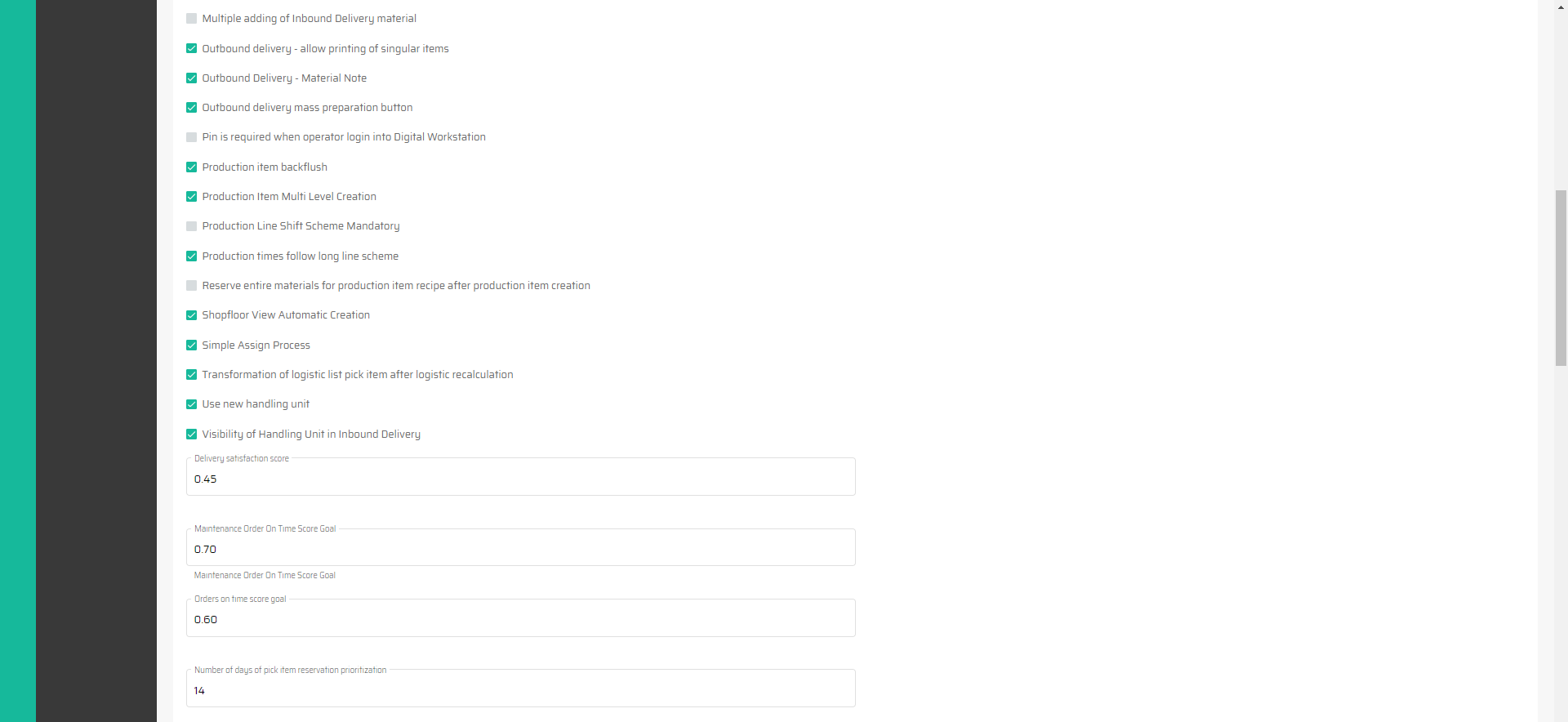

Multiple adding of Inbound Delivery material | Checkbox | On/Off | Enables the option to add more than 1 item to Inbound Delivery. |

Outbound delivery - allow printing of singular items | Checkbox | On/Off | Enables printing of a form for individual Outbound Delivery items. |

Outbound Delivery - Material Note | Checkbox | On/Off | Displays the option to add a note to specific Outbound Delivery items. |

Outbound delivery mass preparation button | Checkbox | On/Off | Enables bulk processing of Outbound Deliveries. |

Pin is required when operator login into Digital Workstation | Checkbox | On/Off | A PIN is required when logging in to Shopfloor View. |

Production item backflush | Checkbox | On/Off |

|

Production Item Multi Level Creation | Checkbox | On/Off | Activate the function of multi-level links between Production Items. It is necessary to use the Gantt chart of the production order plan. |

Production Line Shift Scheme Mandatory | Checkbox | On/Off | Defines whether it is mandatory to define a Shift template or Shift module for a Production Line. |

Reserve entire materials for production item recipe after production item creation | Checkbox | On/Off | If activated, the entire amount of Warehouse Material is always reserved for production within the definition of consumption. |

Shopfloor View Automatic Creation | Checkbox | On/Off | If activated, the shopfloor view is automatically pre-created when a new production line is created. |

Simple Assign Process | Checkbox | On/Off | A simplified process of assigning a production item to a line is used - dragging an item to a line automatically starts the assignment process without a verification dialog. |

Transformation of logistic list pick item after logistic recalculation | Checkbox | On/Off | |

Use exact quantity when receiving / shipping deliveries | Checkbox | On/Off | If “On”, Inbound Delivery Materials and Outbound Delivery Materials are switched to status Received/Shipped only when exact and full quantity is received/shipped. If “Off”, Inbound Delivery Materials and Outbound Delivery Materials are marked as Received/Shipped when first reception/shipping was done (no matter which quantity was received/shipped). |

Use new handling unit | Checkbox | On/Off | |

Visibility of Handling Unit in Inbound Delivery | Checkbox | On/Off | The Handling Unit Template is displayed in the Inbound Delivery detail. |

Delivery satisfaction score | Chars | Free text | Marker value for dashboard widget - Delivery Satisfaction Score. |

Maintenance Order On Time Score Goal | Chars | Free text | Marker value for dashboard widget - Maintenance Order On Time Score. |

Orders on time score goal | Chars | Free text | Marker value for dashboard widget - Orders on time score. |

Number of days of pick item reservation prioritization | Chars | Free text | |

Count of email for summary sending | Chars | Free text | The maximum number of emails in summary email notifications. |

Default changeover time | Chars | Free text | Definition of the default changeover time, which is taken into account if it is not defined for material pairs, material groups or production lines. |

Number of weeks of generating logistic list runs | Chars | Free text | Definition of the number of weeks how far in advance logistic runs are generated. |

Reason code of incomplete palette | Chars | Free text | Database ID for reason code Incomplete Pallet. |

Recache time interval | Chars | Free text | |

Recache time interval in hours | Chars | Free text | |

Safety time for outbound delivery - seconds | Chars | Free text | |

scheduled_days | Chars | Free text | The number of days how far in advance shifts are generated. |

Time period for summary sending | Chars | Free text | |

Default Handling Unit color visualization | Defined values |

| Defines on which screens the color highlighting of the Handling Unit Template information should be applied. |

Default Production Item Creation Strategy | Defined values |

| Default strategy settings for creating Production Items. It can be manually changed during the creation process.

|

Defines target of data archivation | Defined values |

| Choosing the destination location of the archive files. |

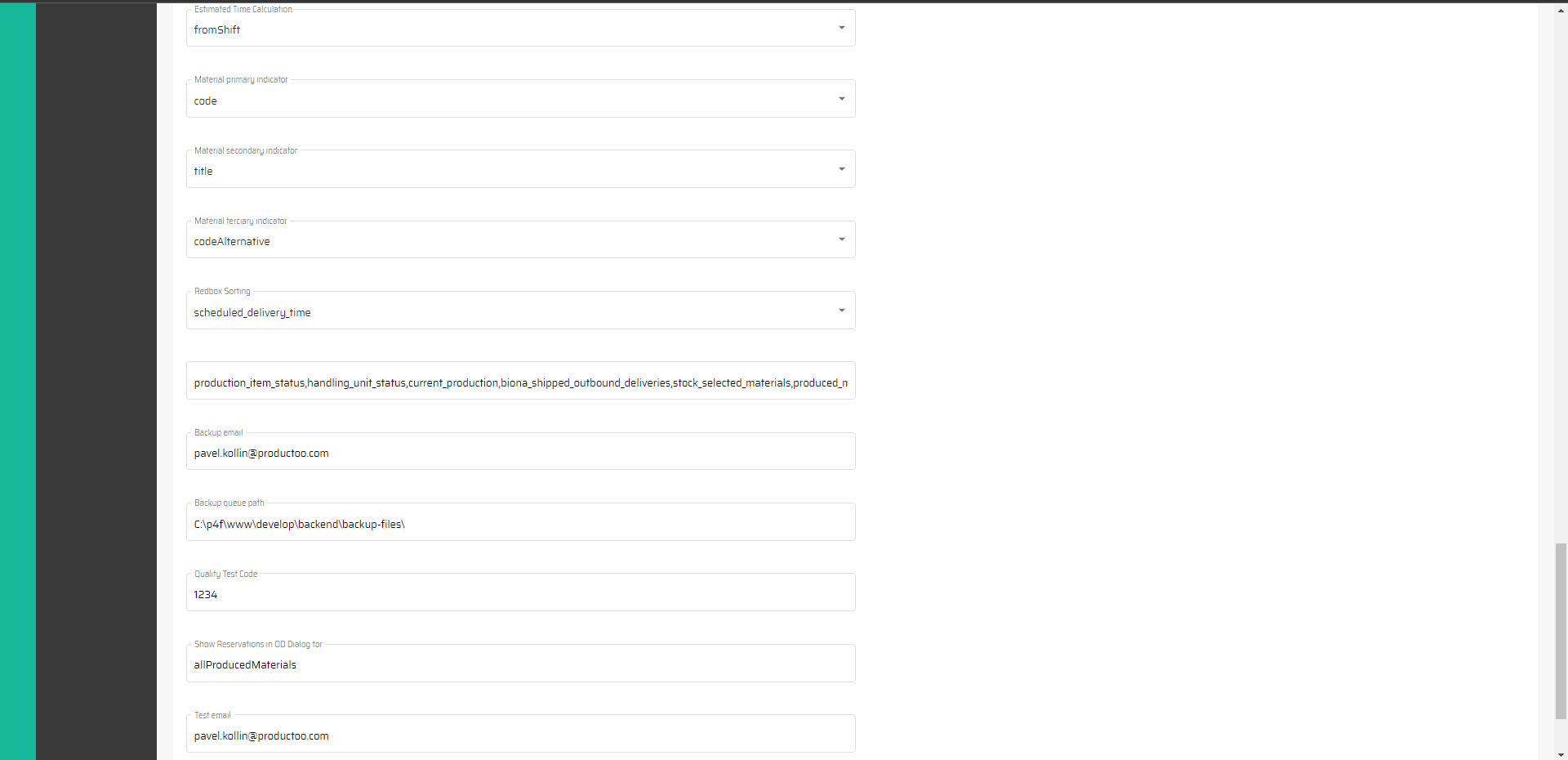

Estimated Time Calculation | Defined values |

| |

Material primary indicator | Defined values |

| Defines what data is used as material primary information in the whole application, if not differently specified for speci user. |

Material secondary indicator | Defined values |

| Defines what data is used as material secondary information in the whole application, if not differently specified for speci user. |

Material terciary indicator | Defined values |

| Defines what data is used as material tertiary information in the whole application, if not differently specified for speci user. |

Redbox Sorting | Defined values |

| Defines the default Redbox sorting. |

Backup email | Chars | Free text | Definition of the email address to which the backup data should be sent. |

Backup queue path | Chars | Free text | Definition of the folder path to which the backup data should be saved. |

Quality Test Code | Chars | Free text | |

Show Reservations in OD Dialog for | Chars | Free text | |

Test email | Chars | Free text | |

Test email name | Chars | Free text |