Production Widgets

These widgets are focused on production-related data, including production item details, performance metrics, and resource management. They help users monitor and optimize production processes, providing insights into operational efficiency and progress.

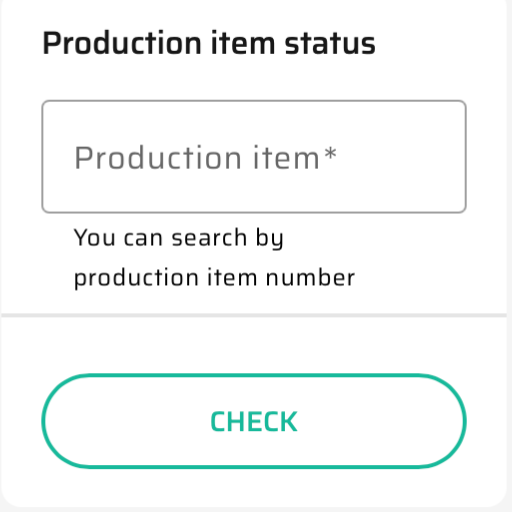

Production item status

The Production Item Status widget lets you quickly find all production items that contain a specific item number. Just enter the item number in the search bar and hit "Enter". The widget will display a list of all relevant production items.

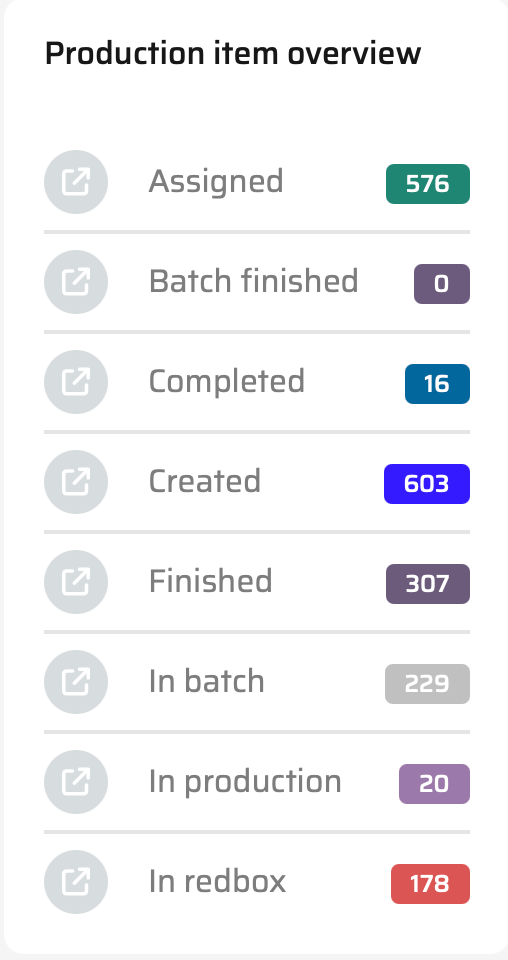

Current production

The Current Production widget displays a list of statuses that production items can be in, along with the number of items in each status. By clicking on a specific status, a dialog window opens, showing a detailed list of items in that status.

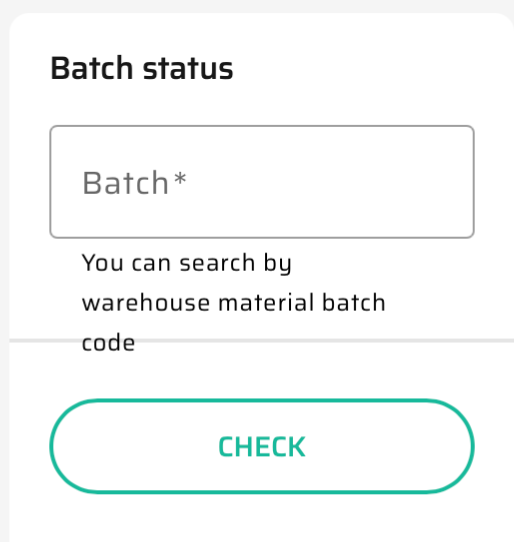

Batch Status

The Batch Status widget allows you to search for batches by batch number. Simply enter the batch number in the search bar and hit "Enter". The widget will then display all batches containing that number.

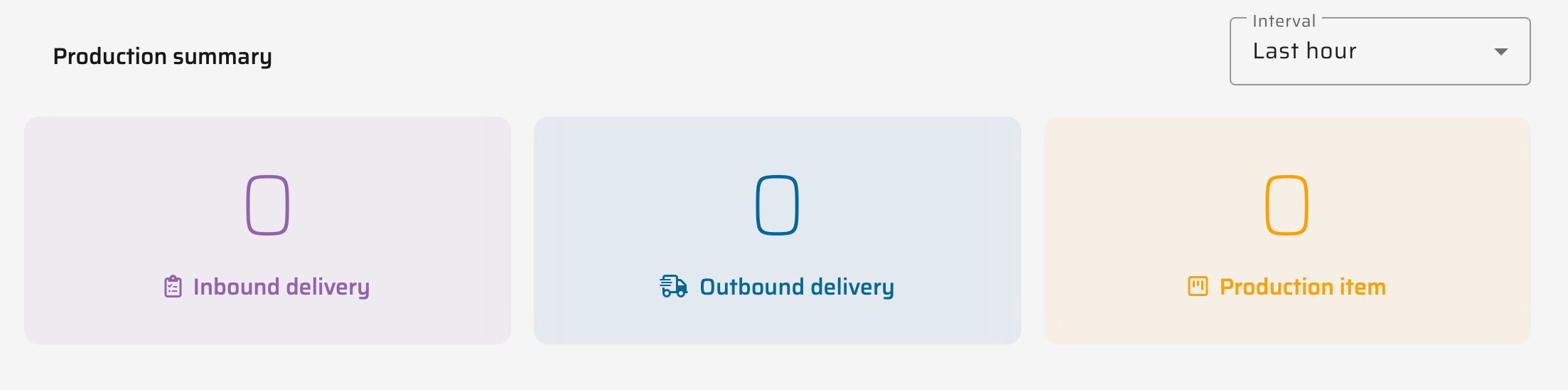

Production Summary

The Production Summary widget displays the number of newly created Inbound Deliveries, Outbound Deliveries, and Production Items over selectable time intervals. You can choose to view data for the last hour, last 7 days, last 30 days, today, or the current year. This widget provides a quick overview of recent production activities.

Production Output

The Production Line Monitoring widget is a tool that allows you to gain an overview of production on a specific production line during a specific time period. This widget provides two main pieces of information: a list of completed master orders and the total quantity of these orders.

Filtering by Production Line and Time Period

Before displaying data, you can filter the widget by a specific production line and time period. This way, you get a tailored view of the production you're interested in.

List of Completed Master Orders

Once you input the desired filter values, the widget will show you a list of master orders that could be completed thanks to the production on the chosen line during the selected period. This means the widget does not track specific products but rather master orders and the quantity of material needed to complete them.

For example, if you have a master order with an ordered quantity of 5 units, requiring 5 units of material A, 5 units of material B, and 5 units of material C, all manufactured on the same line, the widget will indicate that this master order was completed once all the necessary materials were produced in full quantity. In situation, when 5 units of material A, 5 units of material B, and only 3 units of material C were finished, than only 3 units of master order could be finished.

Total Quantity of Completed Master Orders

The second crucial piece of information provided by the widget is the total quantity of completed master orders. This includes the sum of all master orders that could be produced during the specified time period on the selected production line.

In this way, the Production Line Monitoring widget allows you to quickly and accurately understand production and the completion of master orders, aiding in better planning and managing your manufacturing processes.

This widget is a powerful tool for optimizing the production process, enabling you to gain insights into which master orders were completed due to your production on the chosen line during the specified time frame.

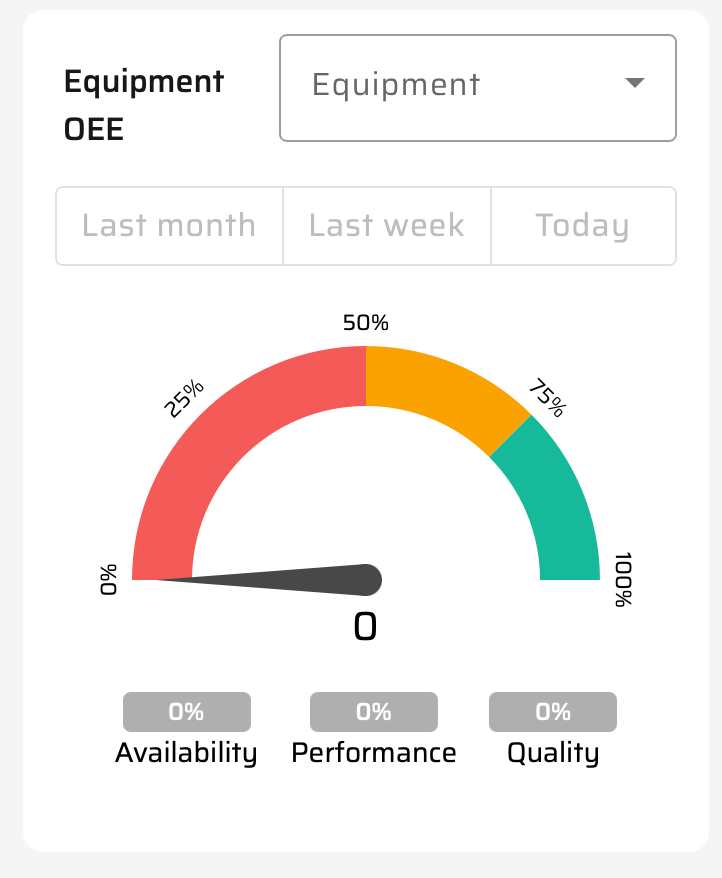

Equipment (Production tool) OEE

The Equipment OEE widget is a gauge-type widget that indicates the Overall Equipment Efficiency (OEE) of a selected production tool used in production within a specified time interval (last month, last week, or today).

This is not Production Line OEE, but OEE of production tool used during production process on specific production items and can be used across multiple production lines.

The OEE is calculated based on the following formula:

OEE = Availability x Performance x Quality = (B/A)×(D/C)×(F/E)

Where:

A: Net production time (specified by Equipment Calendar setting in its parametrization)

B: Actual production time (sum of actual production time of all Production Items using the equipment)

C: Theoretical number of produced pieces (average fastest tact time of materials produced by the equipment)

D: Actual number of produced pieces (sum of declared quantities assigned to the equipment)

E: Actual number of produced pieces (sum of declared quantities assigned to the equipment)

F: Good pieces (D minus bad quantities, with bad quantities defined by settings)

This widget provides a visual representation of the efficiency of the selected production tool, helping you monitor and improve production processes.

Defect Ratio

The Defect Ratio widget displays the production defect rate for a selected production line and time interval. It calculates the ratio of scrap to declared quantity, helping you monitor the quality of your production processes.

Cycle Time

The Cycle Time widget shows the average time from the start of production until the start of the next item in the queue, including changeovers, for a selected material group and time interval. This metric helps you understand the efficiency and speed of your production cycles.

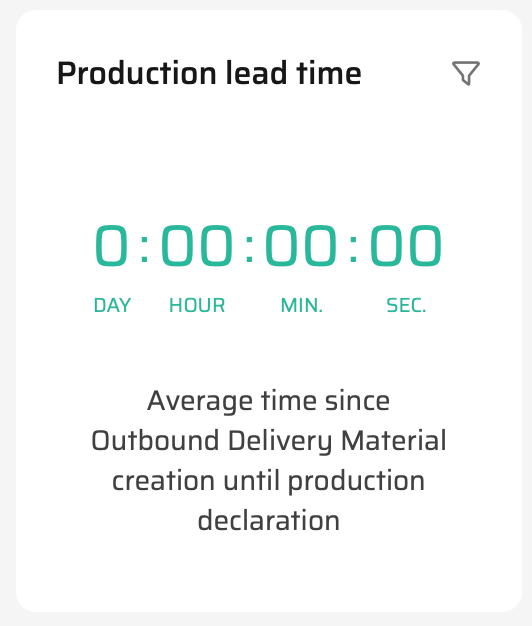

Production Lead Time

The Production Lead Time widget displays the average time from the creation of an Outbound Delivery Material until its production declaration. You can select a specific material and time interval to monitor and improve the lead times in your production process.

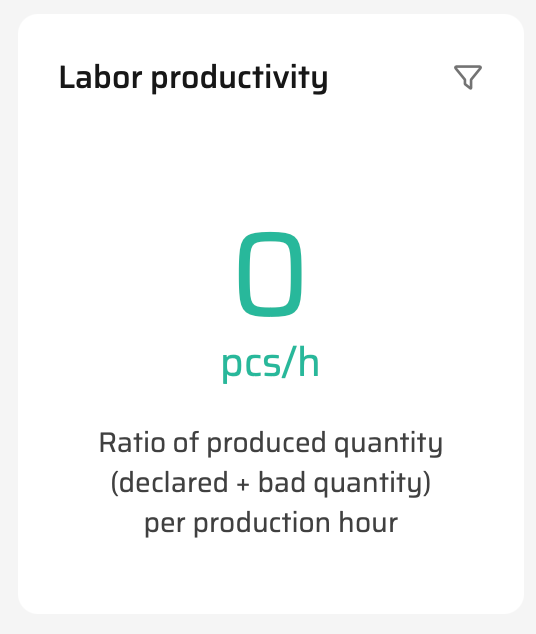

Labor Productivity

The Labor Productivity widget shows the ratio of produced quantity (including both declared and bad quantities) per production hour for a selected production line and time interval. The production hours are defined by planned shifts, providing insights into the efficiency and productivity of your labor force.

Production Reason Codes

The Production Reason Codes widget displays a list of reason codes for why production items were sent to Redbox within a selected time interval (last month, last week, yesterday). It also shows the number of items associated with each reason code, helping you understand common issues in the production process.

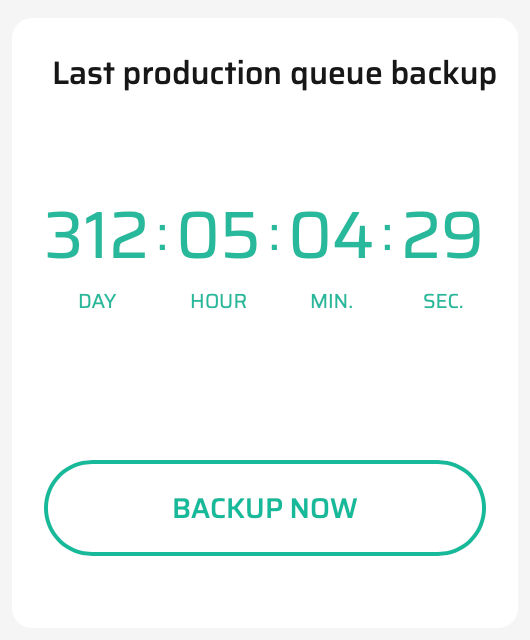

Last Production Queue Backup

The Last Production Queue Backup widget indicates the time elapsed since the last backup of the production queue. It also provides an option to trigger a new backup directly from the widget, ensuring your data is always up to date and secure.