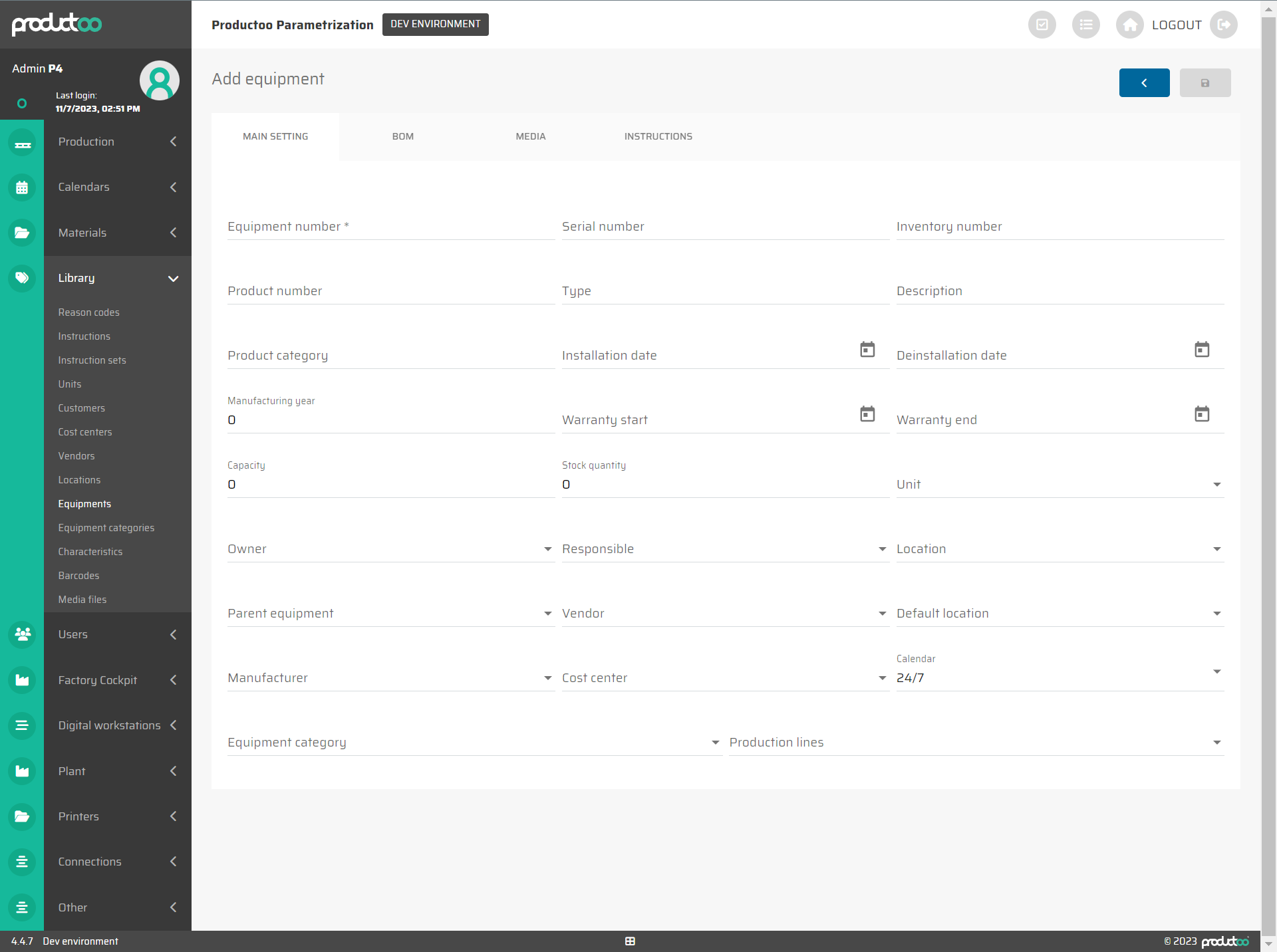

Main Setting - Equipment

In the “Main Settings”, we primarily fill in the basic settings of Equipment.

In the below table, there are all the parameters of the Equipments tab Main Settings with its description.

Parameter name | Limitations | Possible values | Description |

|---|---|---|---|

Equipment Number | 255 chars | Free Text | The number of the equipment (main identificator) |

Serial number | 255 chars | Free Text | Unique identification number assigned to the equipment for tracking purposes |

Inventory number | 255 chars | Free Text | Specific identification code assigned for inventory management |

Product number | 255 chars | Free Text | The manufacturer's assigned number to identify the product |

Type | 255 chars | Free Text | Categorization based on the nature or classification of the equipment |

Product category | 255 chars | Free Text | Grouping based on similar function |

Installation date | MM:DD:RRRR, HH:MM:SS |

| The date when the equipment was initially installed or put into operation |

Deinstallation date | MM:DD:RRRR, HH:MM:SS |

| The date when the equipment was removed from service or decommissioned |

Manufacturing year | number | number | The year in which the equipment was manufactured or produced |

Warranty start | MM:DD:RRRR, HH:MM:SS |

| The commencement date of the warranty period provided by the manufacturer or supplier |

Warranty end | MM:DD:RRRR, HH:MM:SS |

| The termination date of the warranty period, indicating when warranty coverage expires |

Capacity | 0 or positive number | decimal positive number | Capacity of this equipment for production purposes (mixer, mold, etc) |

Description | 255 chars | Free Text | Detailed information or notes about the equipment, including specifications, features, or any relevant additional details |

Stock quantity | 0 or positive number | decimal positive number | Quantity of pieces of this equipment in stock. (If values >1 are used, the possibility of traceability and detailed load analysis is reduced!). |

Unit | defined values | The list of all Units available for selection | The measurement or quantity unit associated with the equipment (e.g., pieces, kilograms, meters) |

Owner | defined values | The list of all Owners available for selection | User responsible for the equipment's ownership and management |

Responsible | defined values | The list of all Responsibles available for selection | User accountable for the maintenance and upkeep of the equipment |

Location | defined values | The list of all Locations available for selection | Location where the equipment is currently placed or stored |

Default location | defined values | The list of all Locations available for selection | Predetermined or primary location set for the equipment within the system |

Parent equipment | defined values | The list of all Equipments available for selection | Relationship indicating if the equipment is part of a larger system or assembly |

Vendor | defined values | The list of all Vendors available for selection | Supplier or company from which the equipment was purchased |

Manufacturer | defined values | The list of all Manufacturers (same list as Vendors) available for selection | Company or entity that produced the equipment |

Cost center | defined values | The list of all Cost centers available for selection | Specific budget or accounting designation where costs associated with the equipment are allocated |

Calendar | defined values | The list of all Calendars available for selection | The "Calendar" serves as the data foundation for calculating the Overall Equipment Effectiveness (OEE) of specific equipment - manufacturing tool used in individual production items, not across entire production lines. (Production Line OEE is calculated with different parameters) |

Equipment category | defined values | The list of all Equipment categories available for selection | Classifying the equipment based on a predefined category or group |

Production lines | defined values | The list of all production lines available for selection | Production lines where this equipment is used (it is not the production line itself, only the use of the tool in production). |