Production Queue

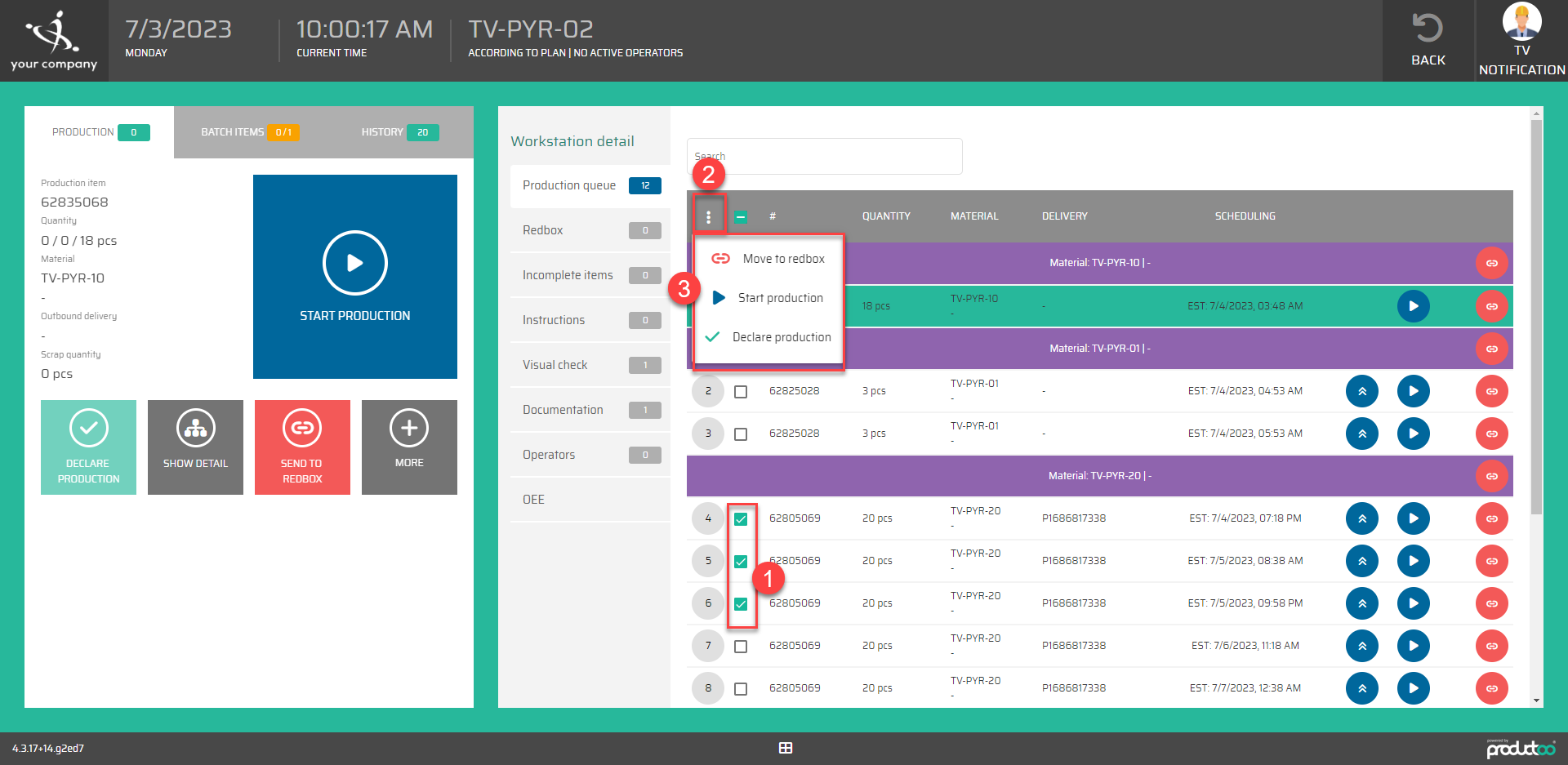

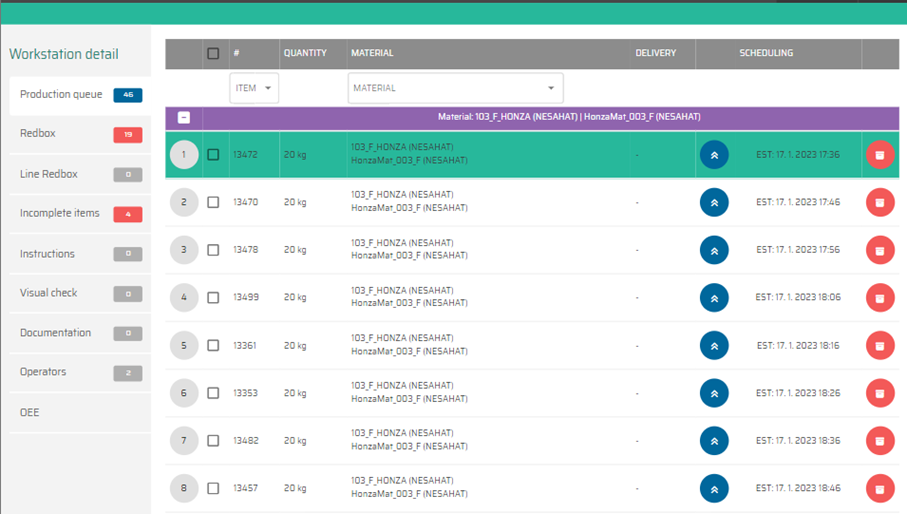

The first tab on the right part of the screen displays the current production queue on the line. Production items are sorted according to the currently set production queue by the production planner, with data about the production item number, produced quantity, material, order number, and the planned time of production completion. After clicking on the specific item, its BOM will be displayed.

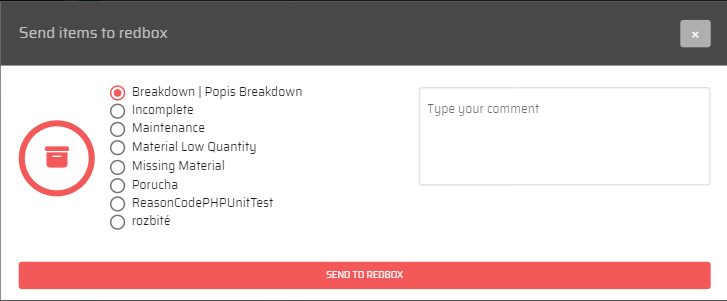

Each of the items can be sent to the Redbox individually by pressing the button :Send_To_Redbox: . A window will appear where we select the reason of why we are sending the production item into Redbox and then will be confirmed by pressing the “Send to Redbox” button.

Mass operations

If the use of mass operations is enabled in the screen configuration, checkboxes will be displayed next to individual items in the production queue. The following operations can be performed on selected items: Send to Redbox, mass Start Production, mass Complete Production. Items started in mass will have the same start time for production. Items declared in mass will have the same completion time. If the function for calculating production time based on moving average is activated on the production line, the average production time of mass-completed items will be evenly distributed to individual items based on their quantity.