OEE - Overall Equipment Efficiency

OEE stands for Overall Equipment Efficiency, and it is a key performance indicator (KPI) used in manufacturing to measure the effectiveness and productivity of a production line or equipment.

OEE is typically expressed as a percentage and is calculated based on three main factors: availability, performance, and quality.

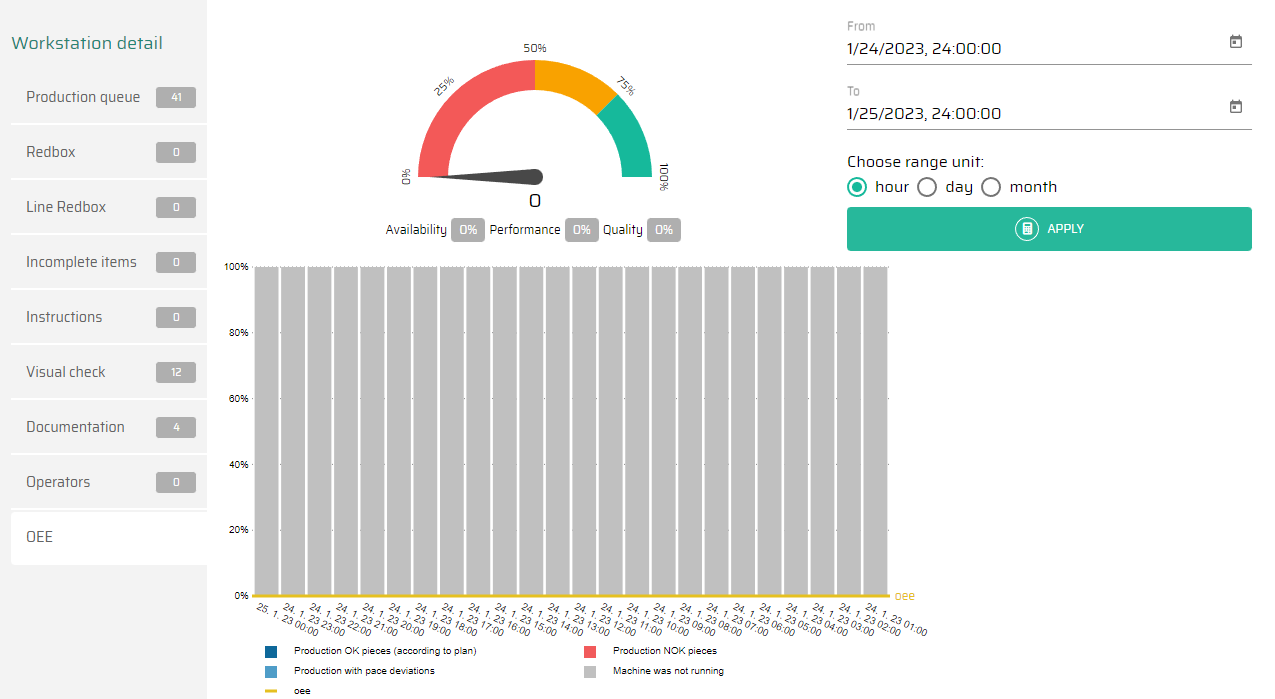

This tab displays the OEE, specifical for this production line. For the measurements, we need to insert the following data:

Parameter name | Limitations | Possible values | Description |

|---|---|---|---|

From | DD:MM:YYYY HH:MM:SS |

| By setting this parameter we set from when the OEE should calculate the efficiency. |

To | DD:MM:YYYY HH:MM:SS |

| By setting this parameter we set it till when the OEE should calculate the efficiency. |

Choose range unit | Checkbox |

| The unit we choose will influence the graph of OEE and will display the efficiency per chosen unit. |

To start the calculation we need to press this button :apply:.

The OEE will procentually calculate:

Availability

Performance

Quality

And the graph will shows the data:

Production OK pieces (according to plan)

Production NOK pieces

Production with pace deviations

Machine was not running

oee