Production loop

In a scenario, when the production is managed by a pull system from logistics, it can be beneficial to apply production loop for material in order to automatically generate number of production items in a loop (to be produced). This will ensure at any specific time, the number of “not closed” production items will match it’s configuration from material master definition for production times. The loop is always specific for each line and cannot be global (spreading across multiple lines).

Production loop

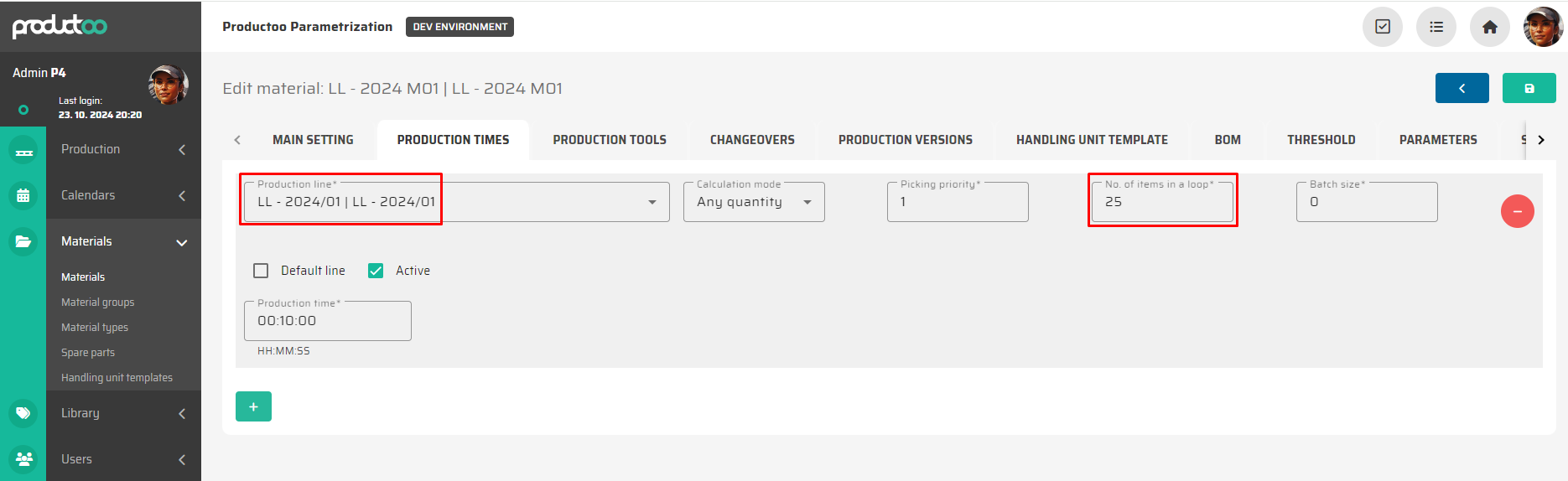

To use a production loop, the definition of number of cards must be provided at the material master level.

In the given example, the number of cards is “25”, which will pre-generate and renew this exact number of production items for the production line “LL - 2024/01”.

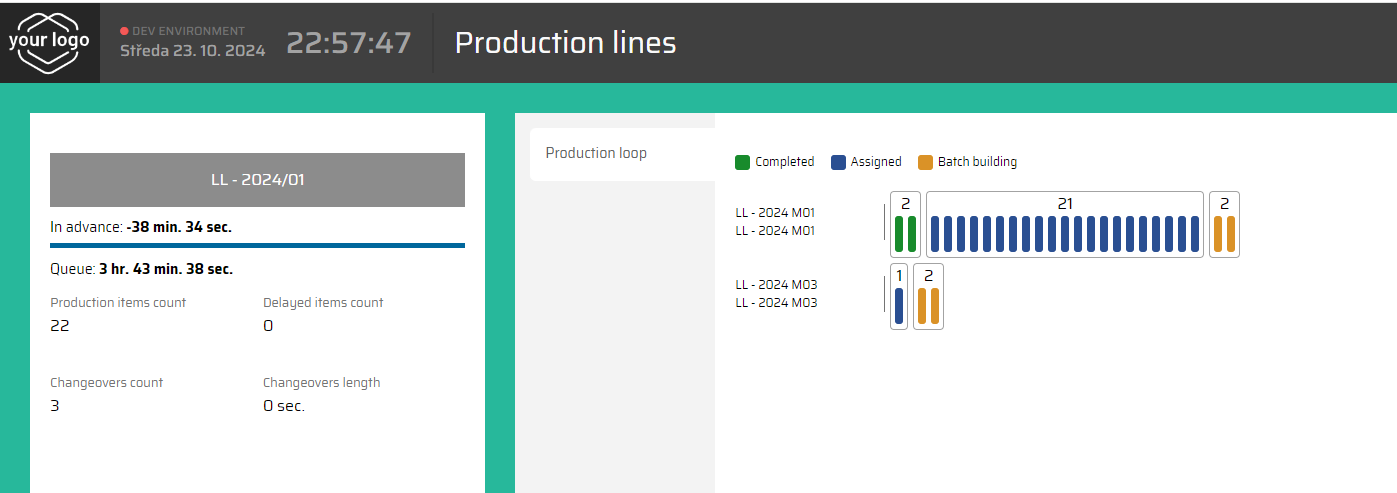

Production loop chart

In order to track the number of cards, there is a possibility to display the data in a form of a chart:

This chart gives us the precise information of how many card we have in which status. Resulting always to the defined number of cards in the previous step (25).

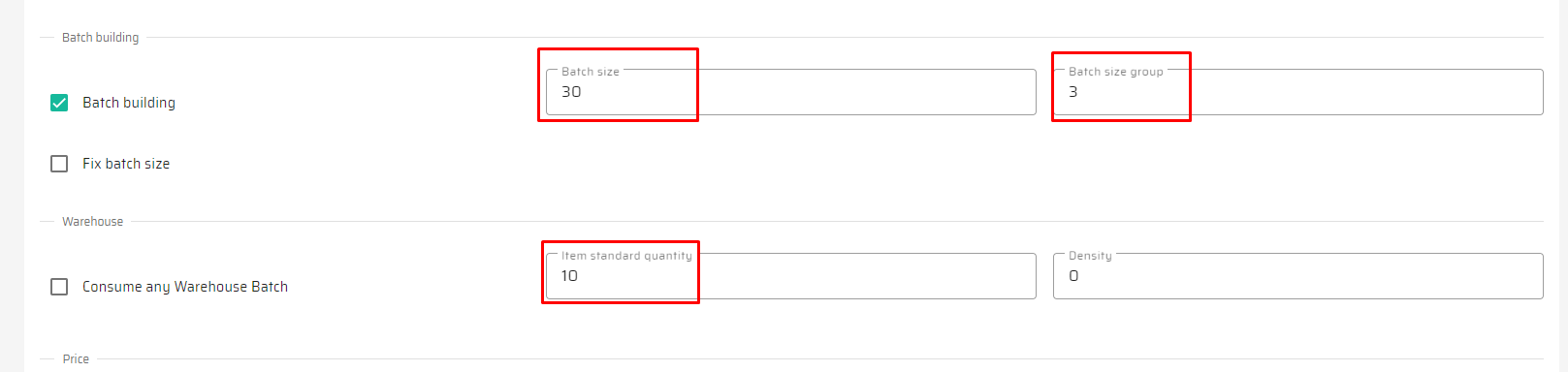

Relation with batch building

We can apply batch building for this process. That will result in creating production times (cards) in batch building, until the batch is full and can be released into production. To apply the rules, we need to turn on “batch building”, define the size for the batch and optionally define the number of batches to be created:

Batch size = quantity until batch is released

batch size group = batch size * batch size group => 90 quantity until batch is released

item standard quantity = quantity for a single production item

The batch building can have two levels, which is defined by the size of batch size group.

Batch size group = 0

When batch size group is 0, the batch building is of a single level.

Batch size group > 0

When batch size group is > 0, the batch building is of two levels.

This can result in two possible outcomes when the option is enabled for “split production item after batch buinding”. The result is strictly following the levels of batch building. Meaning when a have a single level batch, it will release the production items into single items (quantity for each item is 10 x 3). When the batch building has two levels, it will release the top most level (quantity for each item is 30 x 3) and items are released as batches (with 3 single production items 10 x 3).

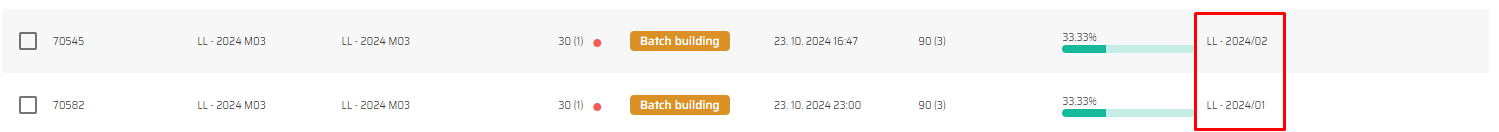

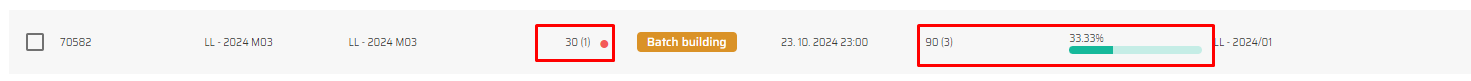

Example of multilevel batch building:

30 (1) tells me that the current size of batch is 1 batch with 30 quantity

the whole batch must contain 3 batches (resulting in quantity of 90)

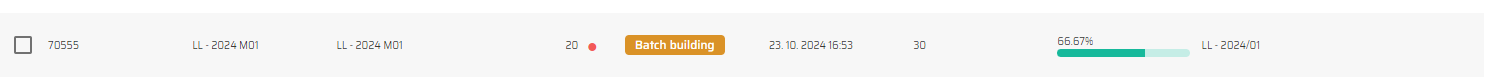

On the other hand, when we have only a single level batch:

quantity is currently 20

the whole batch must contain only a single batch, which is defined to be quantity of 30

When using the batch building together with production loop, the batches are always linked with a production line, on which the production loop is defined. When the production loop is defined for one material and multiple lines, the batch building is separate for each line: