Measuring Point processes

Measuring Points are critical entities that collect data from sensors or counters, such as temperature readers, pressure sensors, or impulse counters. This guide explains how to set up and manage Measuring Points, including configuring breakpoints that trigger specific maintenance actions when certain conditions are met.

What is a Measuring Point?

A Measuring Point is an entity that collects data from a specific sensor or counter. It serves as the interface between the physical sensor and the maintenance management system, allowing for continuous monitoring of equipment conditions. Examples of Measuring Points include:

Temperature Reader: Monitors temperature levels.

Pressure Sensor: Measures pressure within a system.

Impulse Counter: Counts the number of impulses or cycles.

Parametrizing Measuring Points

When setting up a Measuring Point, you can define various parameters to specify how it should operate and what actions should be taken when certain conditions are met.

Breakpoint Rules

Breakpoints are conditions that, when met, trigger specific actions. Each breakpoint has three main parameters:

Comparison Rule: Defines the condition to be met. Options include:

=the current Measuring Point value is equal to X!=the current Measuring Point value is not equal to X<the current Measuring Point value is lower than X>the current Measuring Point value is higher than X<=the current Measuring Point value is lower or equal to X>=the current Measuring Point value is higher or equal to X

Value: The target value X to which the current measuring point value is compared.

Action: Specifies the action to be taken when the breakpoint condition is met. Available actions are:

Create Maintenance Notification - CorrectiveCreate Maintenance Notification - BreakdownCreate Maintenance Order - CorrectiveCreate Maintenance Order - BreakdownNo action

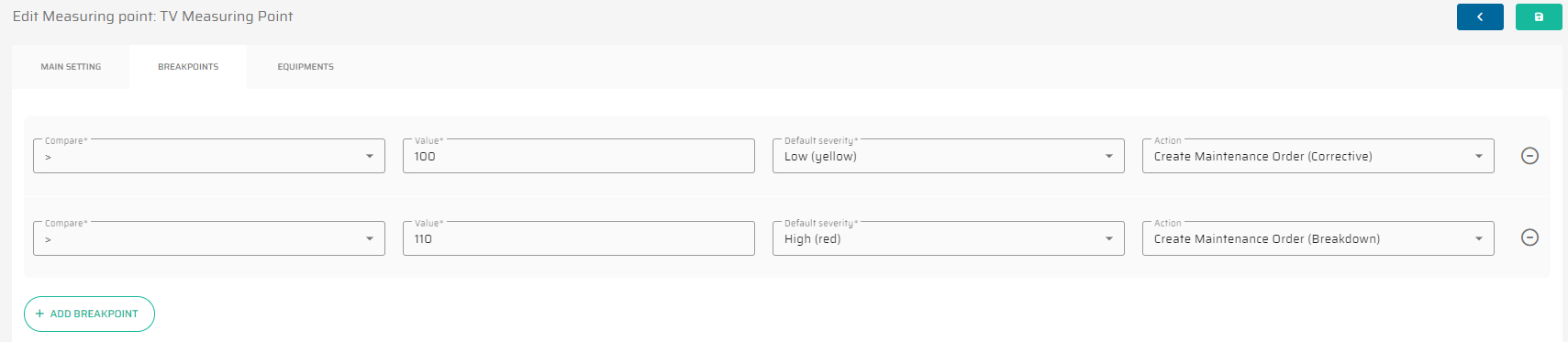

Example Configuration

For instance, if you set a breakpoint with the parameters =; 10; Create Maintenance Notification - Corrective, a new Maintenance Notification of type Corrective will be created when the measuring point value reaches 10. If a notification or order for this breakpoint already exists and is unresolved, no new action will be taken until the existing issue is resolved. Once resolved, the breakpoint will again trigger a new notification or order if the condition is met.

Managing Measuring Points

Measuring Points can be allocated to one or more pieces of equipment. When a breakpoint is triggered, individual notifications or orders are created for each associated equipment.

Steps to Configure a Measuring Point

Create a Measuring Point:

Navigate to the

KPI Definitions parametrizationin the software.Click on

Create New - Measuring Pointand enter the necessary details, such as the title and unit.

Set Breakpoints:

Define one or more breakpoints for the measuring point.

For each breakpoint, specify the comparison rule, value, and action.

Save the configuration to activate the breakpoints.

Allocate Equipment:

Assign the measuring point to one or more pieces of equipment.

Ensure that each piece of equipment has the relevant measuring points set up.

Monitor and Respond:

The system will continuously monitor the measuring point values.

When a breakpoint condition is met, the corresponding action will be executed.

Check for any existing notifications or orders before creating new ones to avoid duplicates.

Preventive Plans and Measuring Points

When creating a Preventive Plan for equipment, you can set separate breakpoints at the levels of:

Preventive Plan: Triggers preventive maintenance actions based on predefined conditions.

Measuring Point: Collects data and triggers actions based on sensor readings.

This allows for flexibility, as the same measuring point can have multiple breakpoints—one directly on the measuring point itself and another on the preventive plan level. Each can trigger different types of maintenance actions, ensuring comprehensive coverage.

Example Scenario

Consider a temperature sensor with the following configurations:

Measuring Point Level:

Breakpoint:

>=; 100°C; Create Maintenance Order - CorrectiveBreakpoint:

>=; 110°C; Create Maintenance Order - Breakdown

Preventive Plan Level:

Breakpoint:

>=; 90°C; Create Maintenance Order - Preventive

If the temperature reaches 90°C, the preventive plan is triggered and new preventive order is created, or already existing one is rescheduled for soone execution.

If the temperature reaches 100°C, Maintenance Order of typ Corrective is automatically created and if the temperature will rise to 110°C and higher, Breakdown Maintenance Order will be generated.

Preventive Maintenance is also described in Preventive Maintenance processes

Conclusion

Measuring Points are essential for effective maintenance management, enabling proactive and reactive maintenance actions based on real-time data. By properly configuring breakpoints and allocating equipment, you can ensure timely and appropriate responses to equipment conditions. For further assistance, refer to the help section or contact support.

Keep your systems running smoothly by leveraging the power of Measuring Points!