Automatic line stoppage

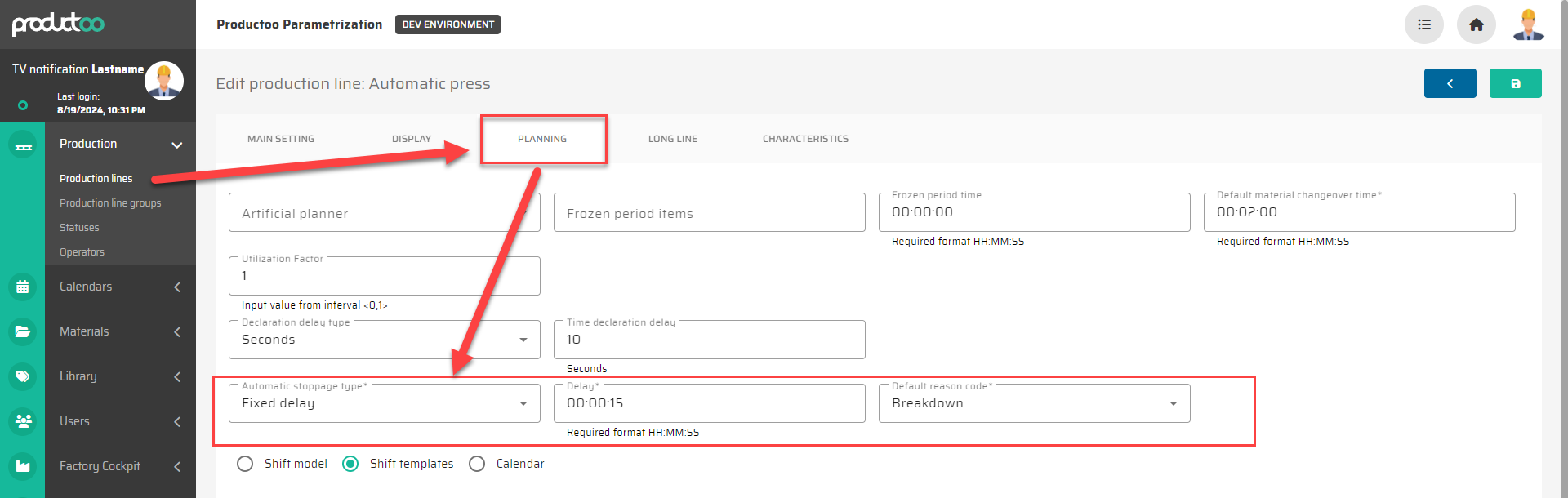

The "Automatic Line Stoppage" feature in the P4 system is designed to automatically pause a production line if no declarations are made within a specified time frame for the current Production Item. This helps with precise time monitoring and resource usage when production stalls. The feature can be customized in the "Production Line Parametrization" module, under the "Planning" tab, where users can select from three modes: "None," "Fixed Delay," and "Percentual Delay."

Configuration Options

1. None

Description: The "Automatic Line Stoppage" feature is disabled. The production line will continue operating regardless of the time between product declarations.

2. Fixed Delay

Description: The line will be paused if no declaration is made within a fixed period after the next estimated declaration.

Configuration:

Trigger Time Calculation: The system calculates the trigger time as follows:

Trigger time >= Last Declaration Time* + Item Tact Time** + Fixed Delay TimeIf no declaration is made by the trigger time, the production line is automatically paused.

3. Percentual Delay

Description: The line will be paused if no declaration is made within a time frame that is a percentage of the tact time after the next estimated declaration.

Configuration:

Trigger Time Calculation: The system calculates the trigger time as follows:

Trigger time >= Last Declaration Time* + Item Tact Time** + Percent of Tact TimeIf no declaration is made by the trigger time, the production line is automatically paused.

How It Works

Process Initiation

When a Production Item is started on the line, the "Automatic Line Stoppage" feature remains inactive until the first declaration (first completed unit) is made.

After the first declaration, the system begins monitoring the time between declarations.

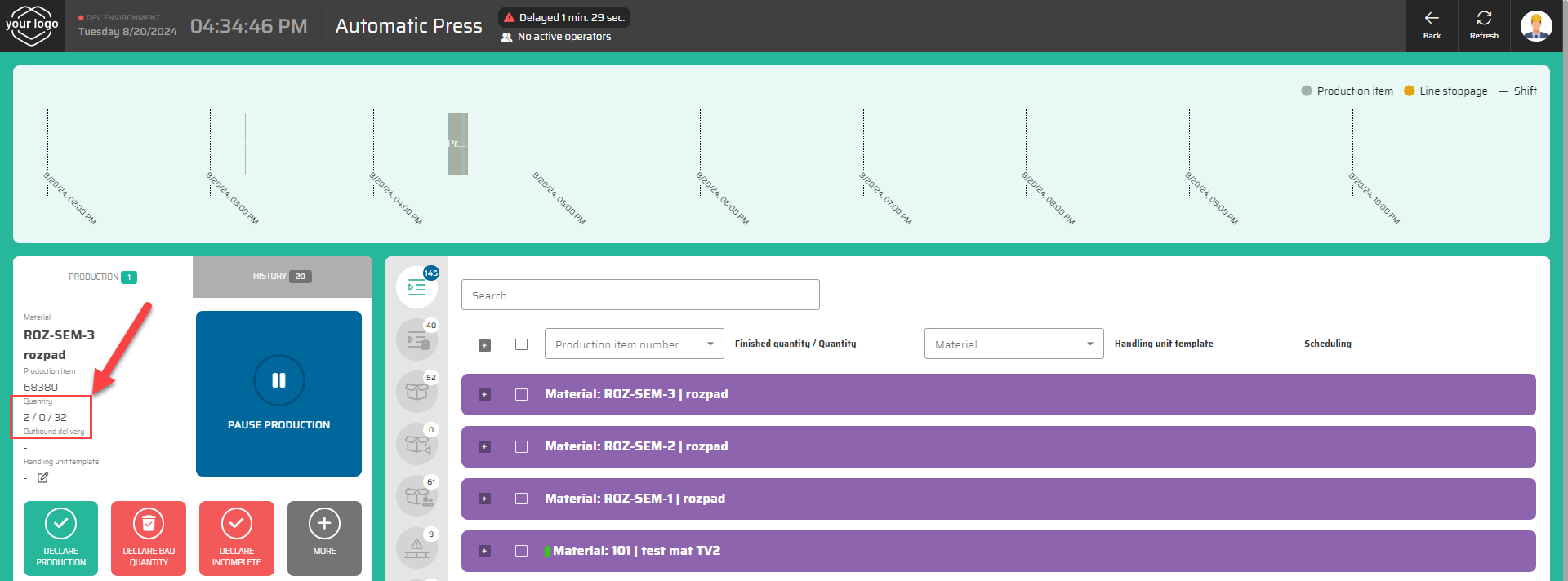

Triggering a Line Stoppage

The system continuously checks the time elapsed since the last declaration.

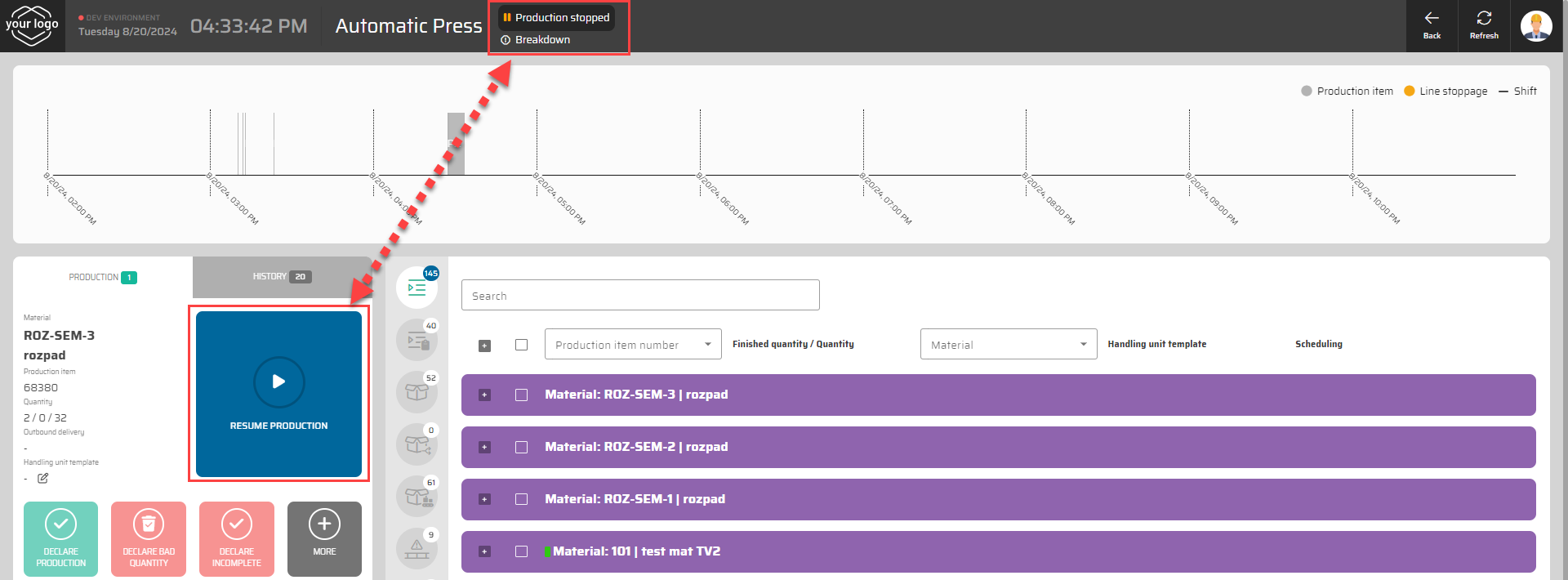

If the calculated trigger time is reached without a new declaration being made, the production line will automatically be paused.

All Production Items currently in progress on the line will be set to the "Paused" status.

The system will log the stoppage with a pre-configured reason code.

Resuming Production

There are two ways to resume production after an automatic stoppage:

Manual Declaration:

An operator can manually restart the line by pressing the designated button on the interface.

After restarting production, the system will again begin monitoring for the next declaration.

Automatic Declaration:

If declarations are automatically triggered by machine signals (OPC UA connection), the line will automatically resume as soon as the next signal is received, along with the first declaration.

The monitoring process will reset and continue as per the configured delay settings.

Key Terms

*Last Declaration Time: The timestamp of the most recent executed declaration on the production line.

**Tact Time: The estimated time between declarations based on the production item.

Example Use Case

Imagine a production line with a tact time of 10 minutes and a Fixed Delay of 5 minutes. If the last declaration was made at 10:00 AM, the next declaration is expected by 10:10 AM. If no declaration is made by 10:15 AM (10:00 + 10 minutes + 5 minutes), the system will automatically pause the line, ensuring that operational time of the production line is recorded precisely for reporting purposes.