Maintenance Formulas

This documentation provides detailed explanations of the formulas used to calculate various KPIs, both event-based and periodic. These KPIs are crucial for monitoring and improving the efficiency of maintenance processes.

Event KPIs

Event KPIs are calculated during the execution of Maintenance Orders (MOs) and provide real-time insights into the maintenance process. Below are the formulas used for each event KPI:

Maintenance Order Duration Time

Formula:

Duration Time = MO Finish Time − (MO Creation Time or MO Start Time)

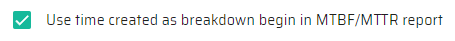

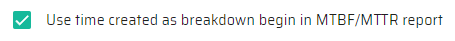

The specific time used depends on the parameter in Settings - Maintenance: use_time_created_breakdown_begin

Reaction Time

Formula:

If Maintenance Notification (MN) is connected to the Maintenance Order (MO):

Reaction Time = MO Start Time − MN Creation Time

If Maintenance Notification is not connected to the Maintenance Order:

Reaction Time = MO Start Time − MO Creation Time

Time From Last Failure

Formula: This KPI is calculated only for MOs of the type "breakdown". The previous MO must meet the following conditions:

Time Finish < Current MO Time Finish

Same Equipment

Breakdown Type

Status is completed

If the parameter in Parametrization - Settings - Maintenance is unchecked

TFLF = MO Time Start − Previous MO Time Finish

If the parameter in Parametrization - Settings - Maintenance is checked

TFLF = MN Time Created − Previous MO Time Finish

if Maintenance Notification is connected

TFLF = MO Time Created − Previous MO Time Finish

if no Maintenance Notification is connected

Spent Time

Formula:

Spent Time = (MO Finished − MO Start Time) × Number of Technicians

The number of technicians is determined from the history of the MO, counting all assigned technicians at any given time.

Downtime

Formula:

Downtime = MO* Time Finished − MN* Time Created

if Maintenance Notification is connected

Downtime = MO* Time Finished − MO* Time Created

if no Maintenance Notification is connected

Calculated from Breakdown type of issues only

Total Time

Formula:

If the parameter in Parametrization - Settings - Maintenance is unchecked:

Total Time = MO Time Finished − MO Time Started

If the parameter in Parametrization - Settings - Maintenance is checked:

Total Time = MO Time Finished − MN Time Created

if Maintenance Notification is connected

Total Time = MO Time Finished − MO Time Created

if no Maintenance Notification is connected

Periodic KPIs

Periodic KPIs are stored in the database and used for other calculations. These KPIs provide long-term insights into the performance and reliability of equipment.

Mean Time to Repair (MTTR)

Formula:

MTTR = ∑(MO Total Time) / MO Count

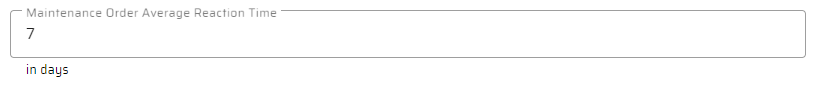

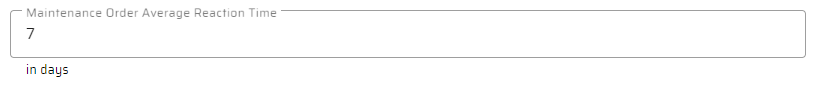

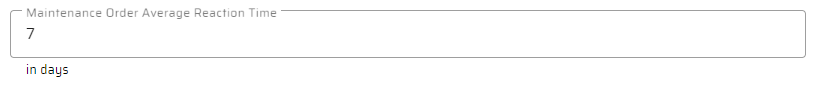

All breakdown MOs connected with the equipment are loaded based on the maintenance_order_average_reaction_time setting in Parametrization - Settings - Maintenance:

Mean Time Between Failures (MTBF)

Formula: All breakdown MOs connected with the equipment are loaded based on the maintenance_order_average_reaction_time setting parameter in Parametrization - Settings - Maintenance:

For each finished MO, the previously finished MO is found, and the time difference is calculated based on the use_time_created_breakdown_begin setting:

Time Between Failure = MO Time Start or Time Created − Previous MO Time Finished

If Time Start or Time Created is higher/lower than Time Finished, the result is 0.

In the case of the first MO in the period:

Time Between Failure = Time Start or Time Created − Initial Time

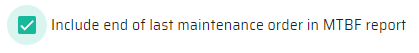

If the parameter in Parametrization - Settings - Maintenance: Include end of last Maintenance Order in MTBF report is active, Time Between Failure is also calculated for the last finished MO and the current time.

MTBF Calculation:

MTBF = ∑(MO Time Between Failure) / MO Count

Average Reaction Time

Formula:

All finished breakdown MOs connected with the equipment are loaded based on the maintenance_order_average_reaction_time setting.

Average Reaction Time = ∑(MO Reaction Time) / MO Count

Conclusion

This documentation provides an overview of the formulas used to calculate various KPIs in our software. Understanding these KPIs and their calculations is essential for monitoring maintenance efficiency and making informed decisions to improve equipment performance. For further assistance, refer to the help section or contact support.

Keep your maintenance processes efficient and data-driven with these KPIs!