Inbound deliveries

Inbound deliveries involve receiving and managing incoming shipments or goods. It includes steps like notification, arrival, unloading, inspection, and storage of the received items.

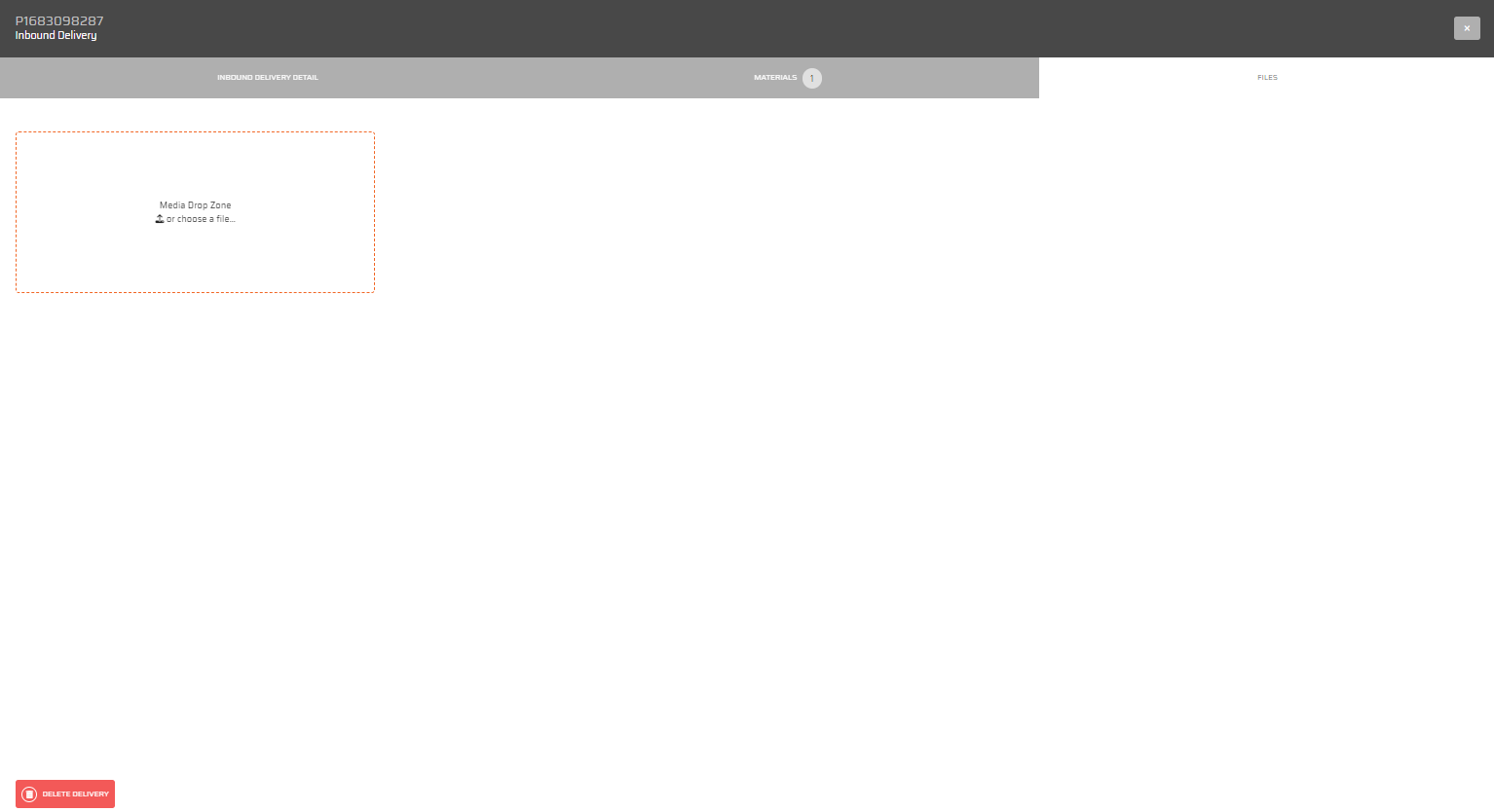

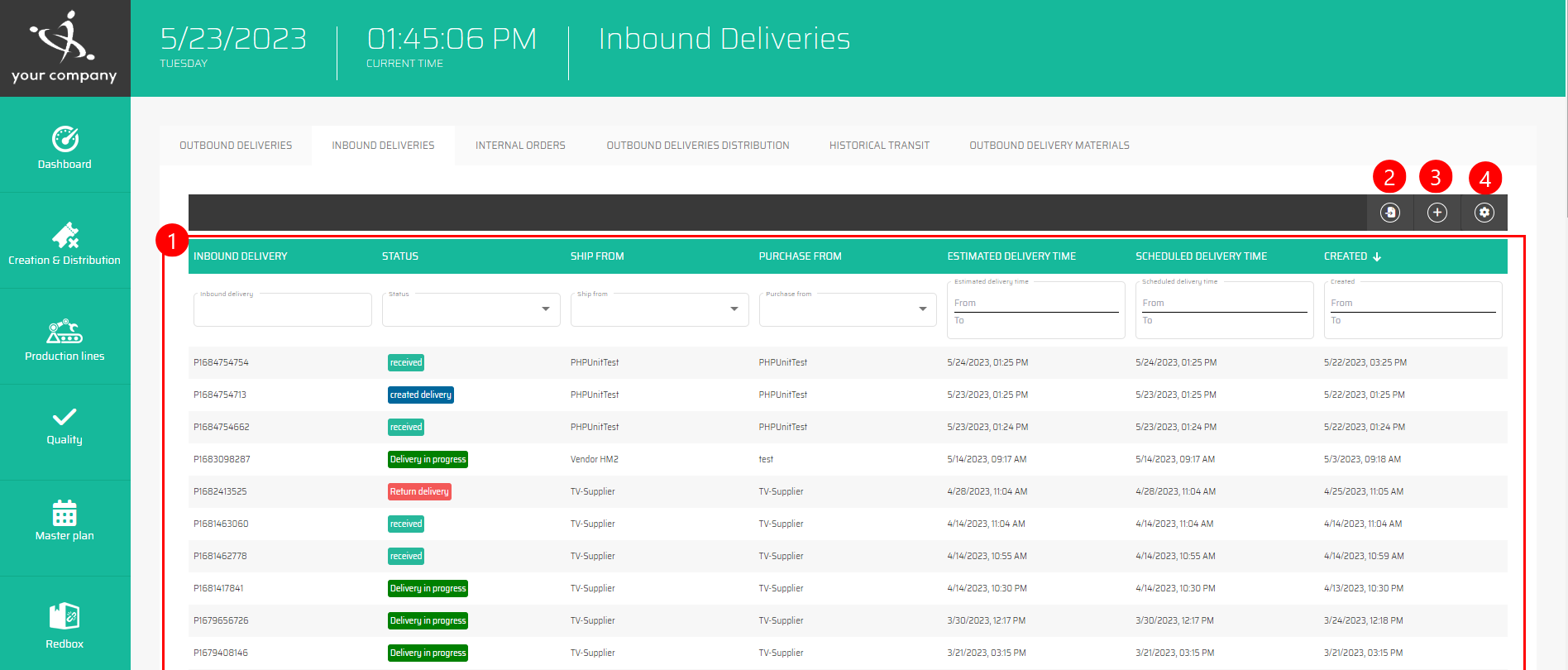

List of all inbound deliveries

Most often orders are imported from another system, the import itself is automatic, but it can be forced using the button :import:, and specifying the concatenated source.

Create an order manually with the button :Add_buttonPC_:

You can change the page layout with customize table :Customize_Table:

The list of all Inbound deliveries can be filtered by all shown columns, it means by:

ID

Inbound delivery

Status

Ship from

Purchase from

Note

Estimated delivery time

Scheduled delivery time

Time created

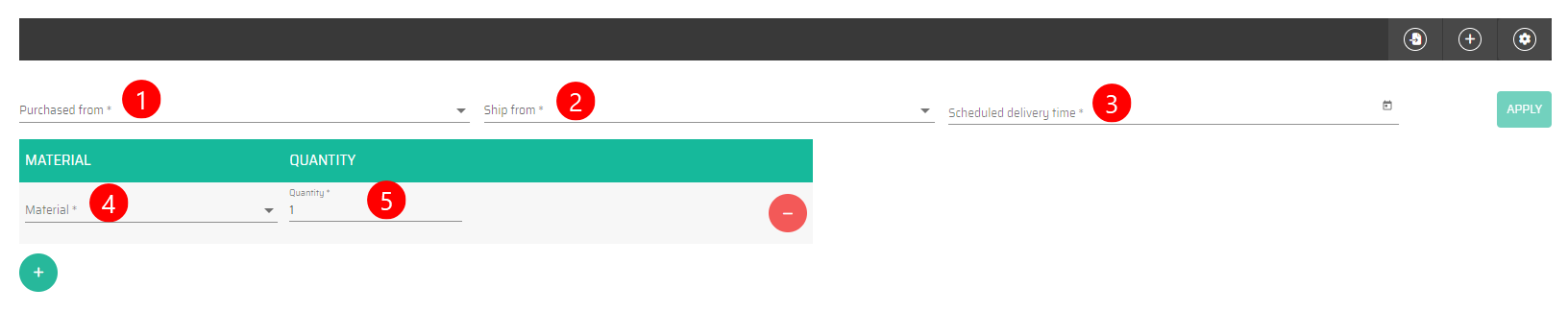

Creation of a new inbound delivery

Create an order manually with the button :Add_buttonPC_:

And save with :apply:.

It the table below you will find all attributes which are possible to insert into this dialog together with its description.

# | Parameter name | Limitations | Possible values | Description |

|---|---|---|---|---|

1 | Sold to | Defined value | The list of customers available for the selection | |

2 | Ship to | Defined value | The list of Customers available for the selection | |

3 | Scheduled Finish time | HH:MM:SS, DD.MM.YYYY | 00:00:00 - 23:59:59, Day and month in the year | |

4 | Scheduled Delivery time | HH:MM:SS, DD.MM.YYYY | 00:00:00 - 23:59:59, Day and month in the year | |

5 | Truck image | Defined value | The list of Truck image available for the selection |